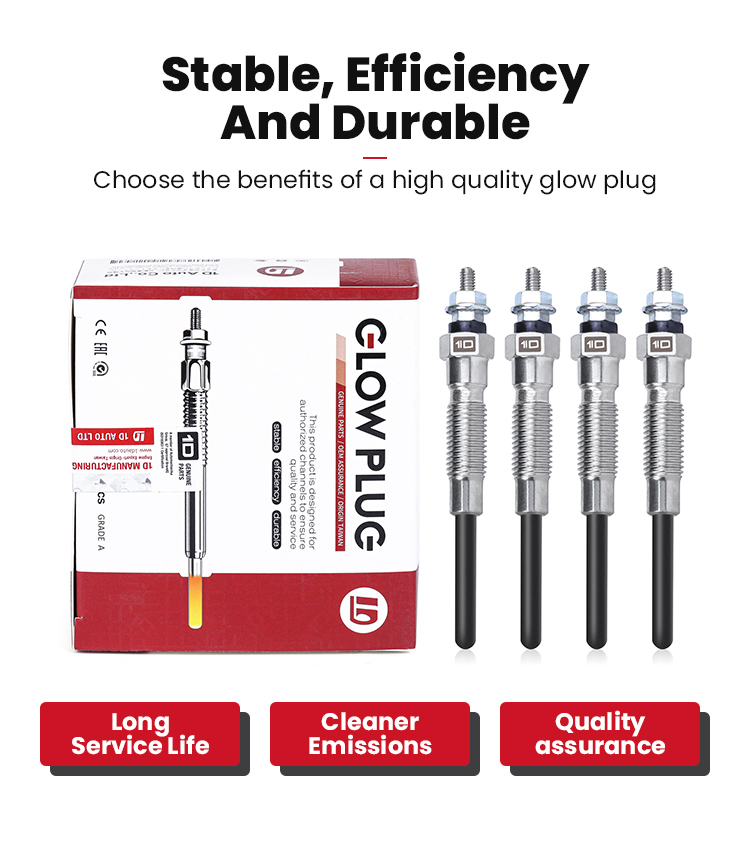

The importance of quality inspection of engine Glow plugs

The quality of the engine Glow plug is directly related to the engine's starting performance and service life. Therefore, strict quality inspection standards are indispensable.

From material properties to finished product functions, a series of standardized testing procedures ensure that each Glow plug can meet the strict usage requirements.

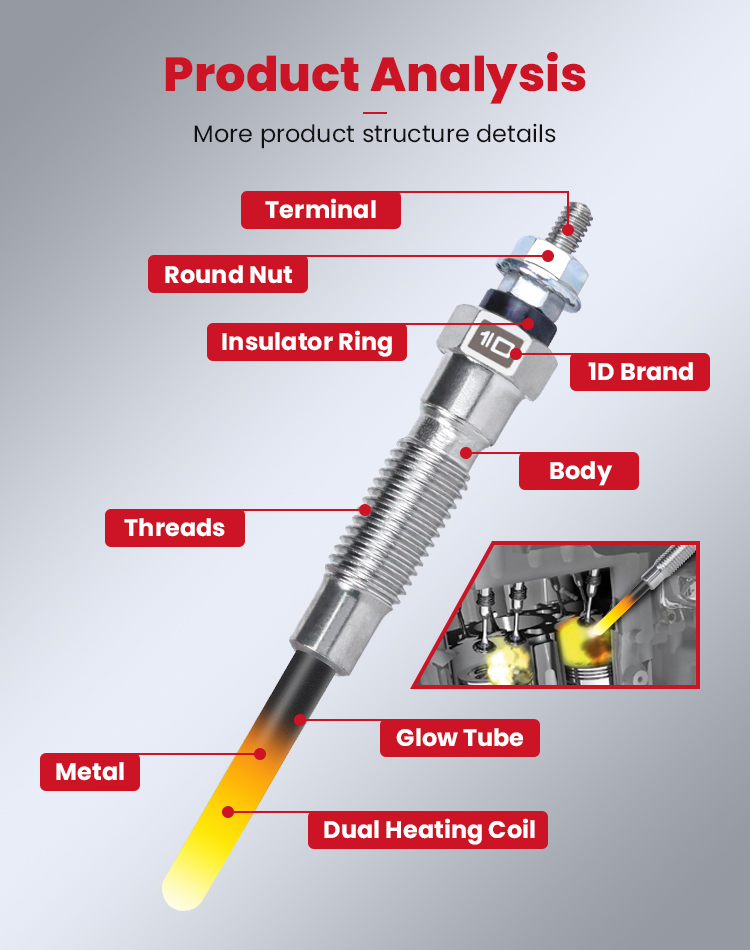

1. In the stage of raw material detection, the composition analysis of the alloy material used in the resistance coil is the key.

Through techniques such as spectral analysis, the proportions of elements like nickel, chromium and iron are precisely determined to ensure that the material's resistivity, oxidation resistance and other properties meet the design standards.

For instance, if the chromium content in a nickel-chromium alloy is lower than the standard value, it will accelerate the oxidation of the resistance coil at high temperatures and shorten the service life of the Glow plug.

For metal casing materials, hardness tests and corrosion resistance tests need to be conducted. The hardness of the casing is measured by a Rockwell hardness tester to ensure that it is not prone to deformation in the complex internal environment of the engine. Salt spray tests were adopted to simulate harsh corrosive environments to detect whether the casing rusted after long-term exposure.

2. During the assembly process of semi-finished products, the quality inspection of the insulation layer is of vital importance.

A high-voltage insulation tester is used to apply a high voltage to the Glow plug filled with insulation material and measure its insulation resistance value. If the insulation resistance is lower than the specified threshold, it indicates that there is a defect in the insulation layer, which may lead to leakage or short circuit.

Meanwhile, X-ray flaw detection technology is utilized to inspect whether there are any defects such as bubbles and cracks inside the insulation layer, ensuring that the insulation layer is uniform and dense, providing reliable insulation protection for the resistance coil.

3. The finished product inspection stage includes multiple functional tests.

First, the heating performance test is carried out. The preheating plug is connected to the analog circuit, and current is applied according to the actual working conditions. An infrared thermal imager is used to monitor the surface temperature distribution and heating rate. It is required that the Glow plug reach the target temperature within the specified time, and the temperature uniformity error be controlled within a very small range.

Secondly, there is the durability test. By means of cyclic power on and off, the usage conditions of the Glow plug throughout the vehicle's entire life cycle are simulated to test whether the resistance value changes within the allowable range and whether the structure is damaged after thousands or even tens of thousands of thermal cycles.

In addition, vibration tests should be conducted. The Glow plug should be fixed on the vibration table to simulate the vibration environment during the engine's operation, and to check whether the connections of each component are firm and whether they will become loose or damaged due to vibration.

4. Environmental protection standards have also become an important part of the quality inspection of modern preheating plugs.

Test whether the wastewater and waste gas generated during the production process of the Glow plug meet the standards, and whether the finished product materials comply with environmental protection requirements, such as whether they contain harmful substances like heavy metals.

Strict quality inspection standards are in place to comprehensively control the quality of the Glow plug from the source to the finished product, providing a solid guarantee for the stable operation of the engine.