Brake when power is off, safe and worry-free

The logistics and production machinery fields often face pain points such as positioning inaccuracy caused by inertial sliding, safety risks caused by sudden power outages, and loss of motor life due to frequent starts and stops.

Your trouble is how to match efficient braking solutions for drive units such as electric tricycle motors to ensure zero errors when parking on slopes and emergency stops. In response to this, helical gear electromagnetic brake motor integrates a power-off brake mechanism, and is equipped with an intelligent electric vehicle controller to achieve flexible electronic brakes (E-ABS) and energy feedback. In actual applications, when the electric tricycle controller cuts off the power, the spring force pushes the armature to press the brake disc, and the motor shaft is locked within 0.1 seconds, eliminating the risk of sliding down the slope and reducing the wear of the mechanical brake pad by 60%.

Core principle:

The motor integrates the worm gear reduction mechanism with the electromagnetic brake module. When powered on, the electromagnetic coil generates suction to compress the spring, release the brake disc, and the motor runs freely; when the power is off, the magnetic field disappears, and the spring resets to make the friction plate clamp the brake disc at high speed to achieve physical shaft locking. Its braking torque is independent of the speed, and it can still park accurately even under low-speed and heavy-load conditions (such as electric tricycles climbing slopes)

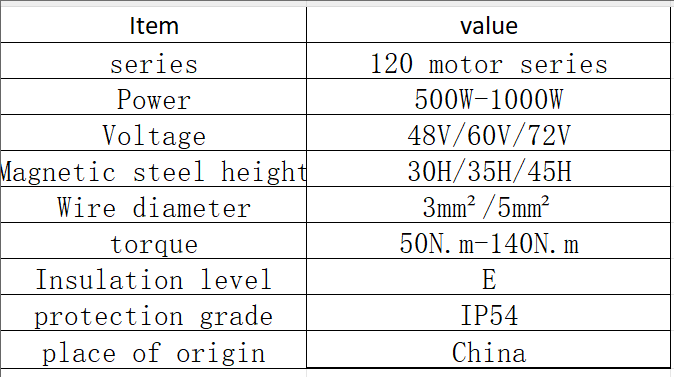

Product Features

Operation tips

Advice from a ten-year maintenance master: When choosing a brake motor, you need to look at the "spring life". The YEJ series brake friction pads can still run at full load after 100,000 start-stop tests, and the braking force does not decay under 75°C high temperature conditions - this is the confidence to "brake" when transporting heavy-loaded tricycles

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Electric tricycle controller,

Electric tricycle motor,

Electric vehicle controller,

Electric tricycle rear axle,

Electric tricycle ,

Electric four-wheel vehicle