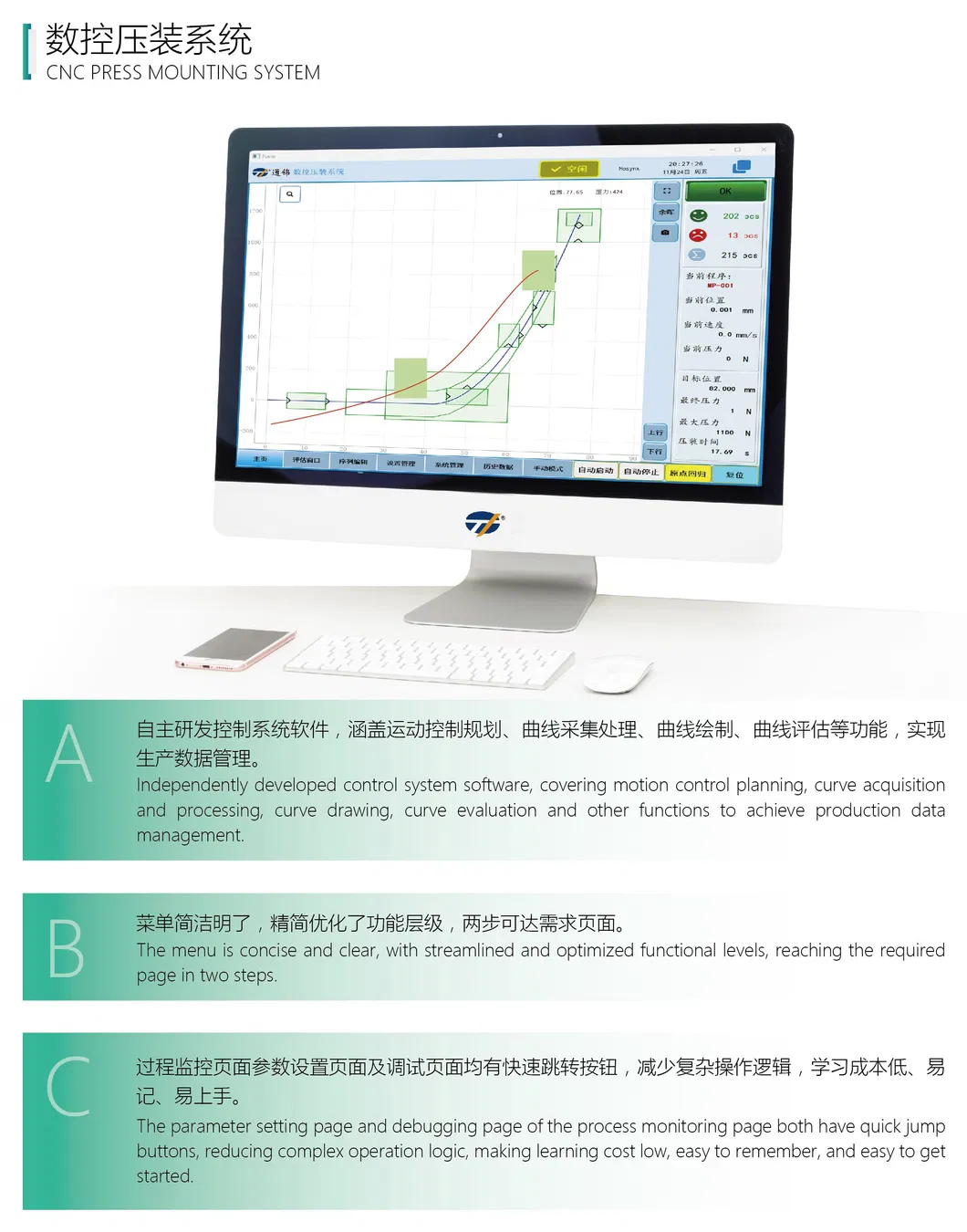

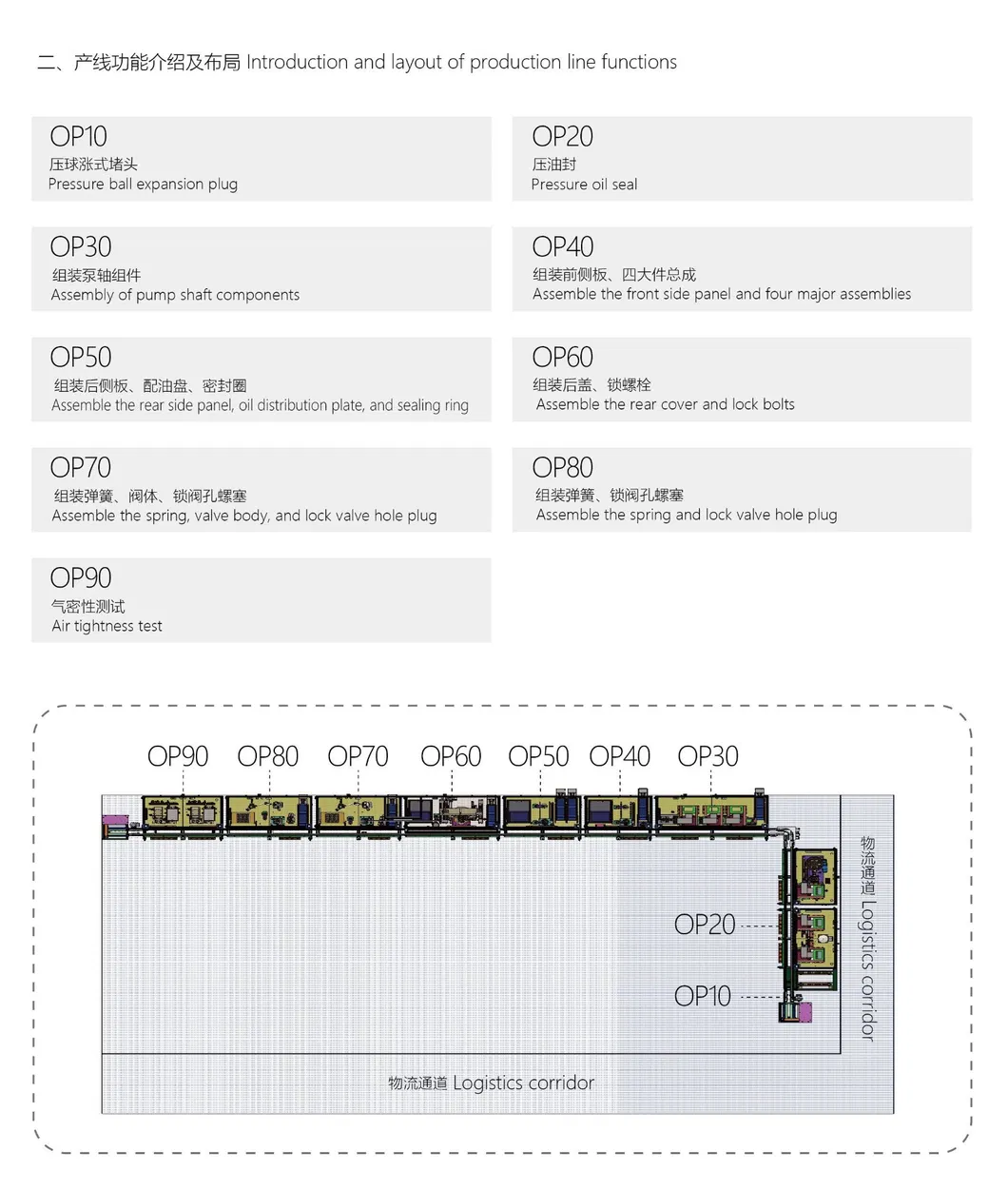

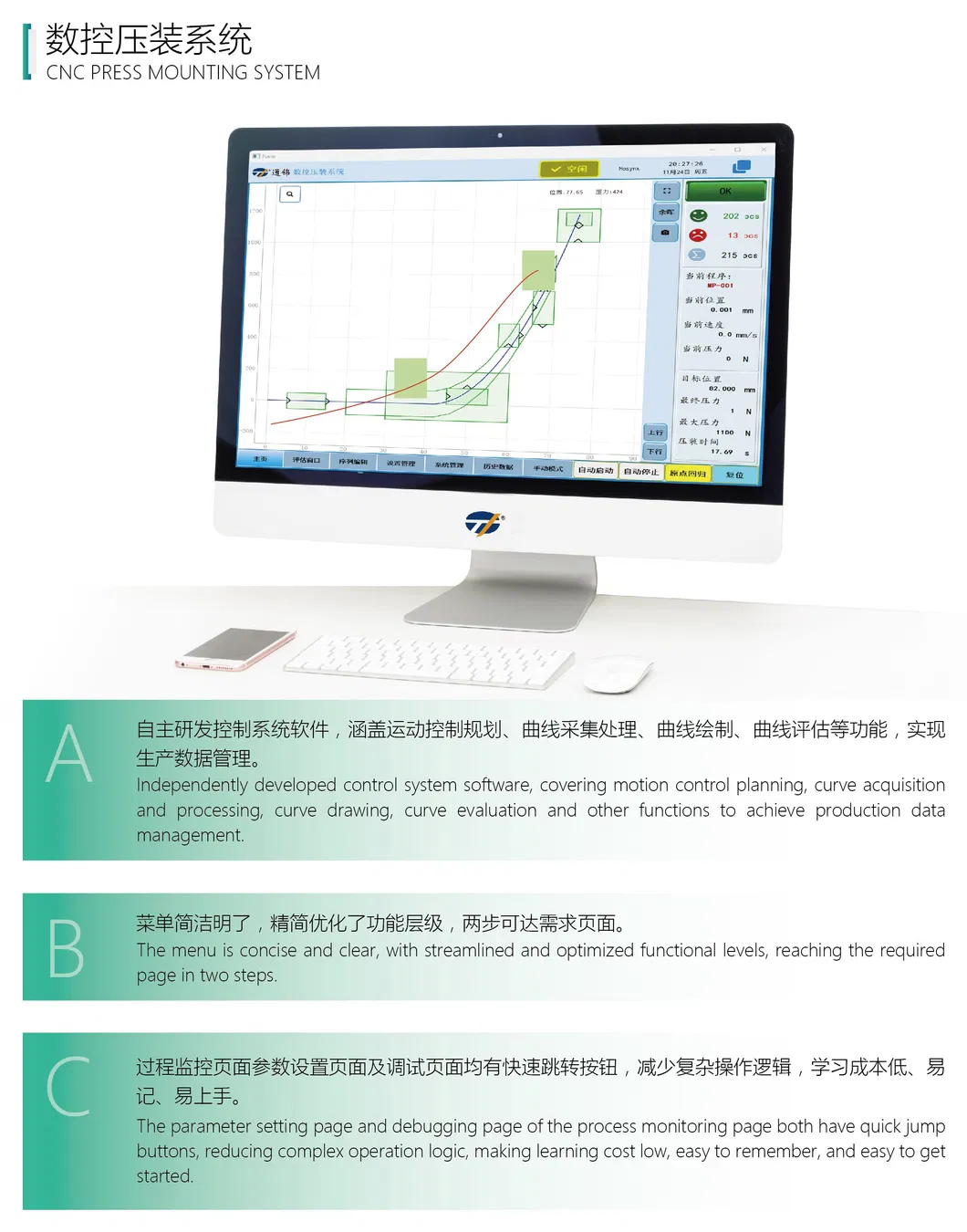

The advanced servo press machine is a state-of-the-art solution designed for high-precision pressing applications across various industries. This intelligent system offers real-time monitoring of both the pressing position and force, enabling immediate detection and adjustment of any interference during the process. By displaying the complete force-displacement curve, it provides an accurate visual representation of the entire pressing operation, eliminating the limitations of traditional presses that lack feedback mechanisms and the inefficiencies of conventional testing machines that cannot support mass production.

One of the key features of this servo press machine is its ability to accurately measure pressure based on predefined pressing depth settings. This functionality compensates for dimensional tolerances during the working process, ensuring the final assembly meets the required precision standards. Additionally, users can define specific zones for quality assessment based on pressure and displacement parameters, allowing for online testing and guaranteeing 100% product compliance during the press-fit process.

The machine offers precise control over the press-fit speed, position, and pressure, making it highly adaptable to different manufacturing requirements. It supports multiple press-fit procedures, including constant speed pressing, precise position stop, force-based stopping, and displacement-controlled stopping. These versatile modes enable efficient execution of multi-stage press-fit tasks without the need for costly precision molds, as the machine's positional repeatability is maintained at ±0.01mm, and pressure control accuracy reaches ±1% of the rated pressure.

In the process of pressing the product, Tongjin servo press machine displays the current pressing position and pressing force in real time, and judges whether the interference is appropriate in time and accurately. At the same time, it displays the pressing curve of the entire force and displacement, which solves the disadvantages of traditional presses that can only be pressed and cannot be detected, and the low efficiency of the testing machine cannot be mass-produced.

The servo press machine can accurately test the pressure according to the set pressing depth, which can compensate for the working dimensional tolerance and ensure the final assembly precision. At the same time, the pressure and

displacement quality judgment area can be set, and online testing can ensure that the product is 100% qualified when press-fit.

The servo press machine can accurately control the press-fit speed, position,and pressure. Setting various press-fit procedures, including constant press-fit speed, setting precise position stop, setting precise force stop, setting precise press-fit displacement stop, and other working modes, makes it easy to complete the requirements of two or more stages of press-fit work. Within the stroke, the precise position of the machine can be arbitrarily set to stop, without the need to use expensive precision molds to ensure the precision of press-fit.

The positional repeatability is ± 0.01mm, and the pressure control accuracy is ±1% of the rated pressure.

Product Parameters

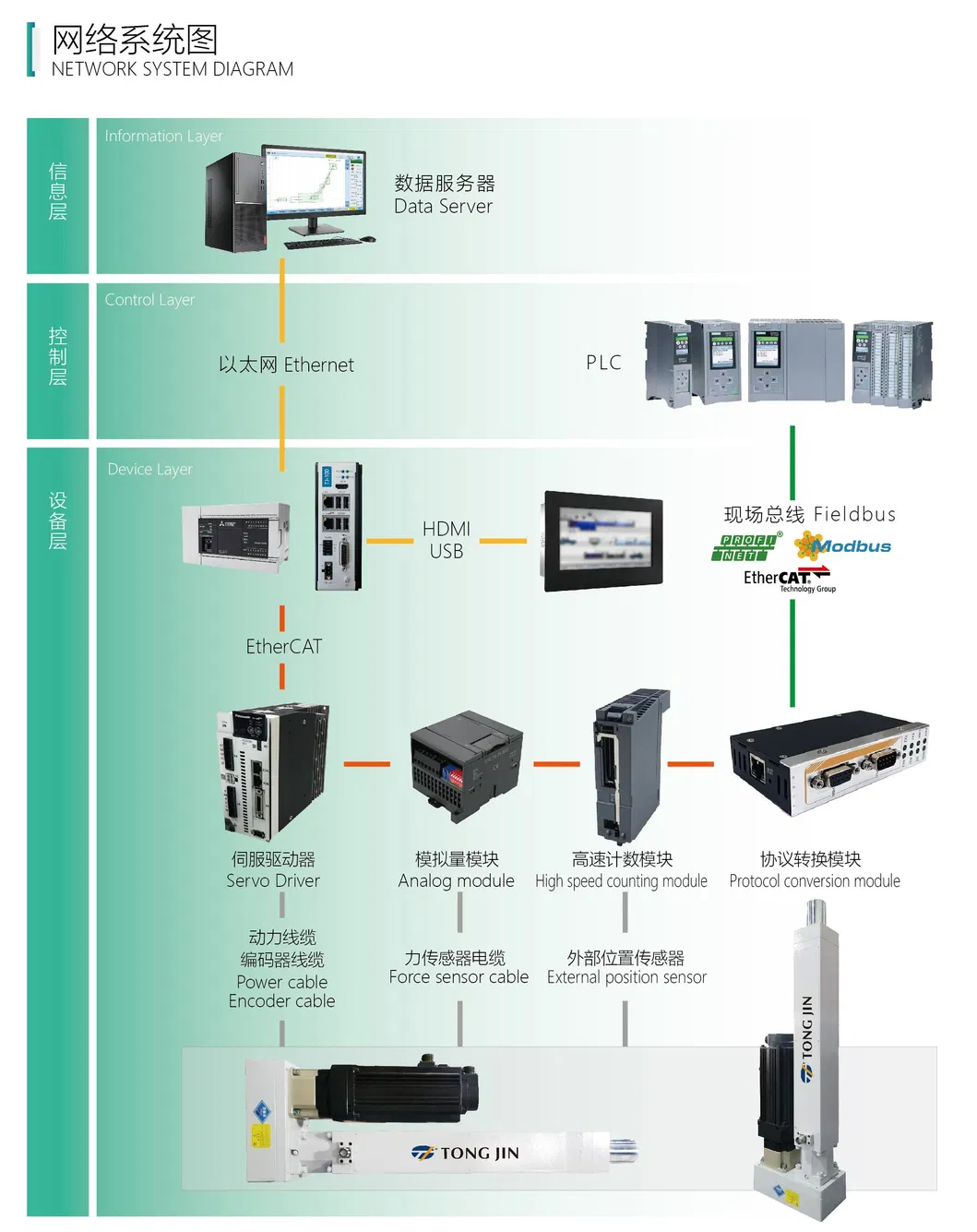

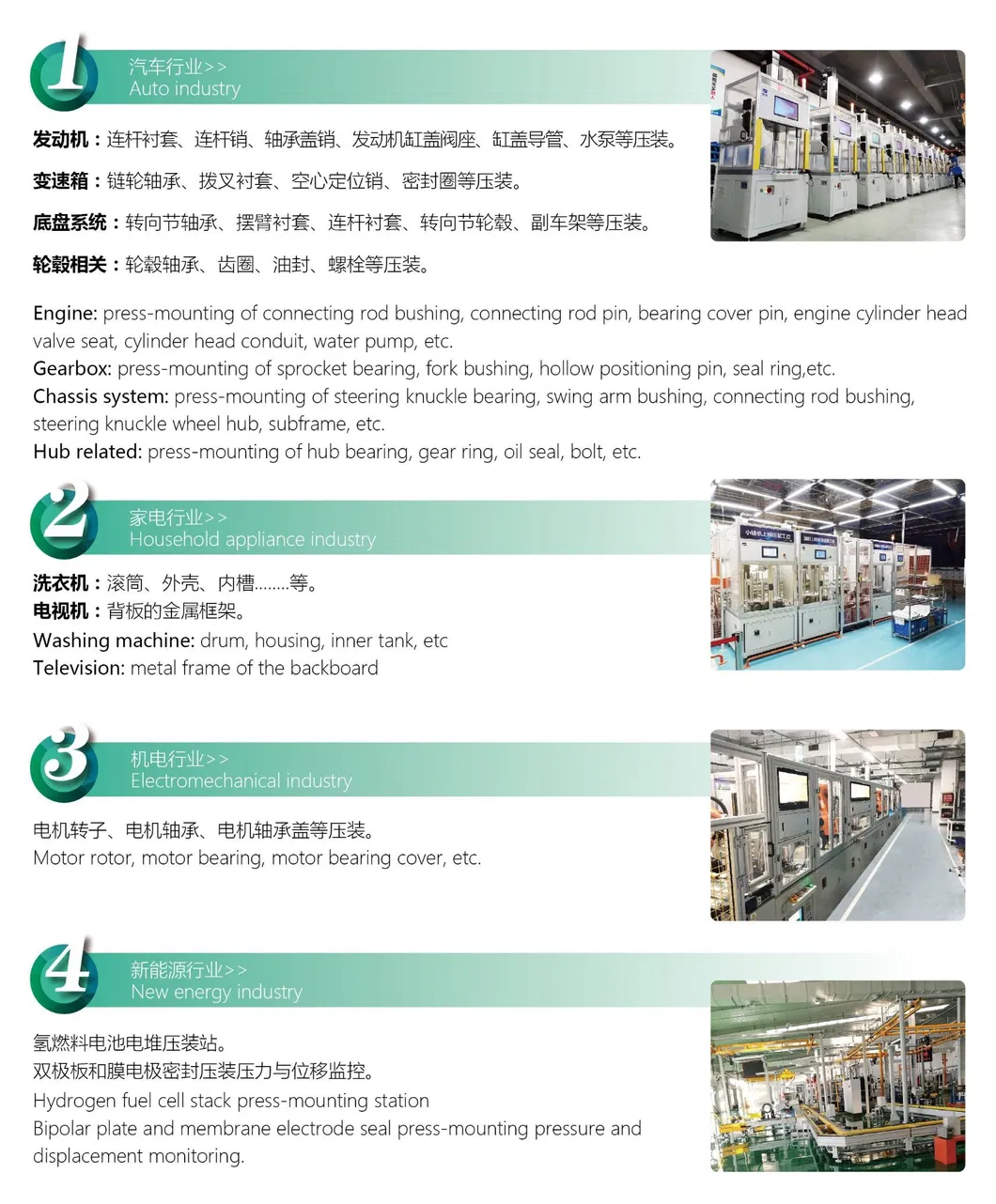

Our company has successfully independently developed independent products such as Tongjin brand servo electric cylinders, intelligent servo press fit machines,Linear Electric Actuators,Heavy Duty Electric Cylinders,Servo Press Machine, etc., combined with six joint robots to achieve automated, safe, and unmanned intelligent assembly green unmanned production lines, providing a one-stop solution for intelligent assembly automation systems in factories.