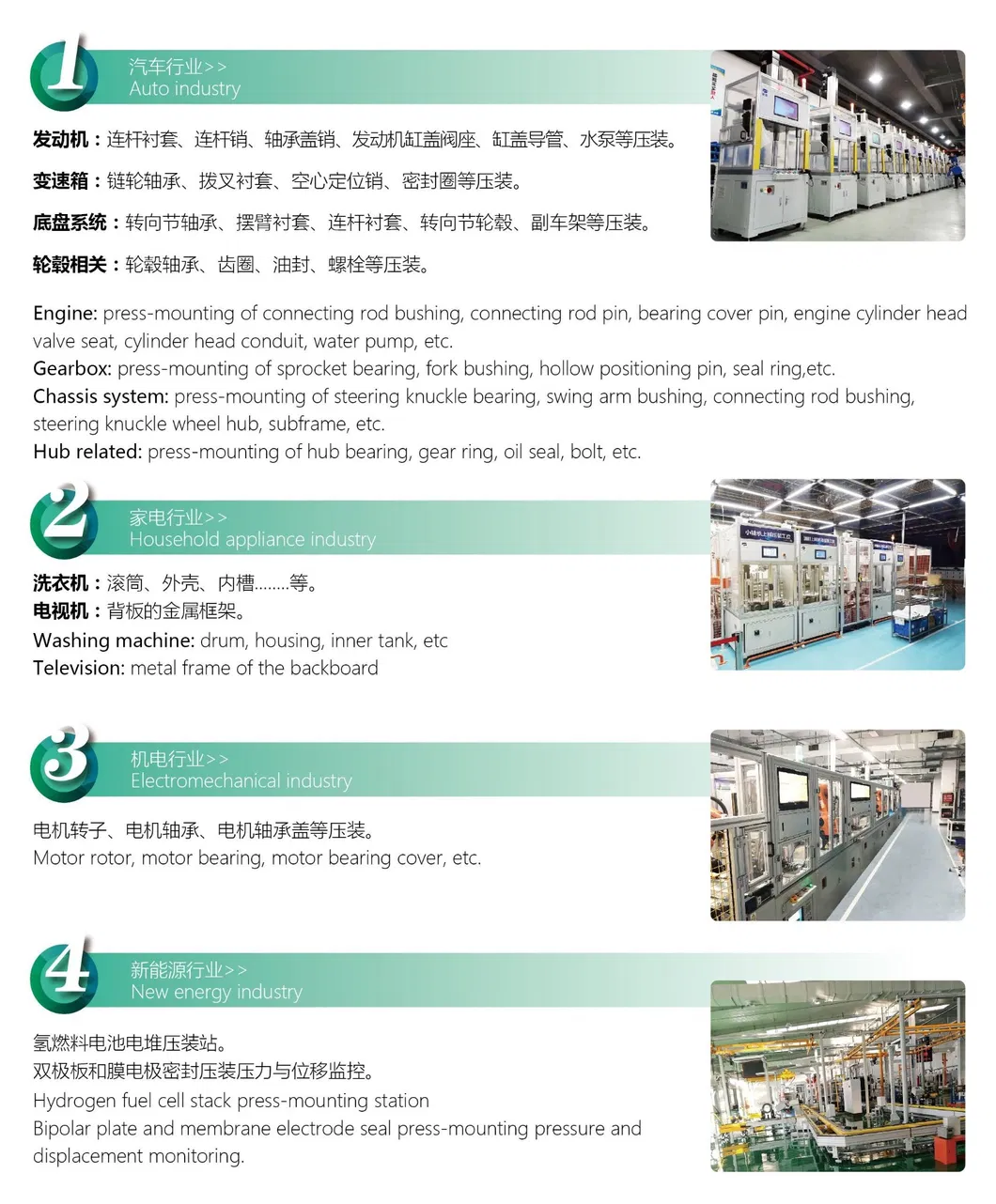

Horizontal Servo Press Fitting Machine, Horizontal Press Machine with Rotor in Stator, and Horizontal Servo Press with Rotor are advanced industrial tools designed for precise and efficient assembly operations. These machines integrate high-precision servo motor technology with robust mechanical systems to ensure consistent performance across a wide range of applications. Whether used in the manufacturing of electric motors, automotive components, or precision engineering parts, these devices offer a reliable solution for pressing, aligning, and assembling components with minimal human intervention.

The Horizontal Servo Press Fitting Machine is specifically engineered for tasks that require controlled force application and accurate positioning. Its horizontal orientation allows for easy integration into existing production lines and facilitates smooth material flow during the assembly process. The inclusion of a rotor within the stator setup makes this model ideal for applications involving motor winding assemblies, where alignment and pressure control are critical. This design ensures that components such as rotors are securely positioned without causing damage to delicate internal structures.

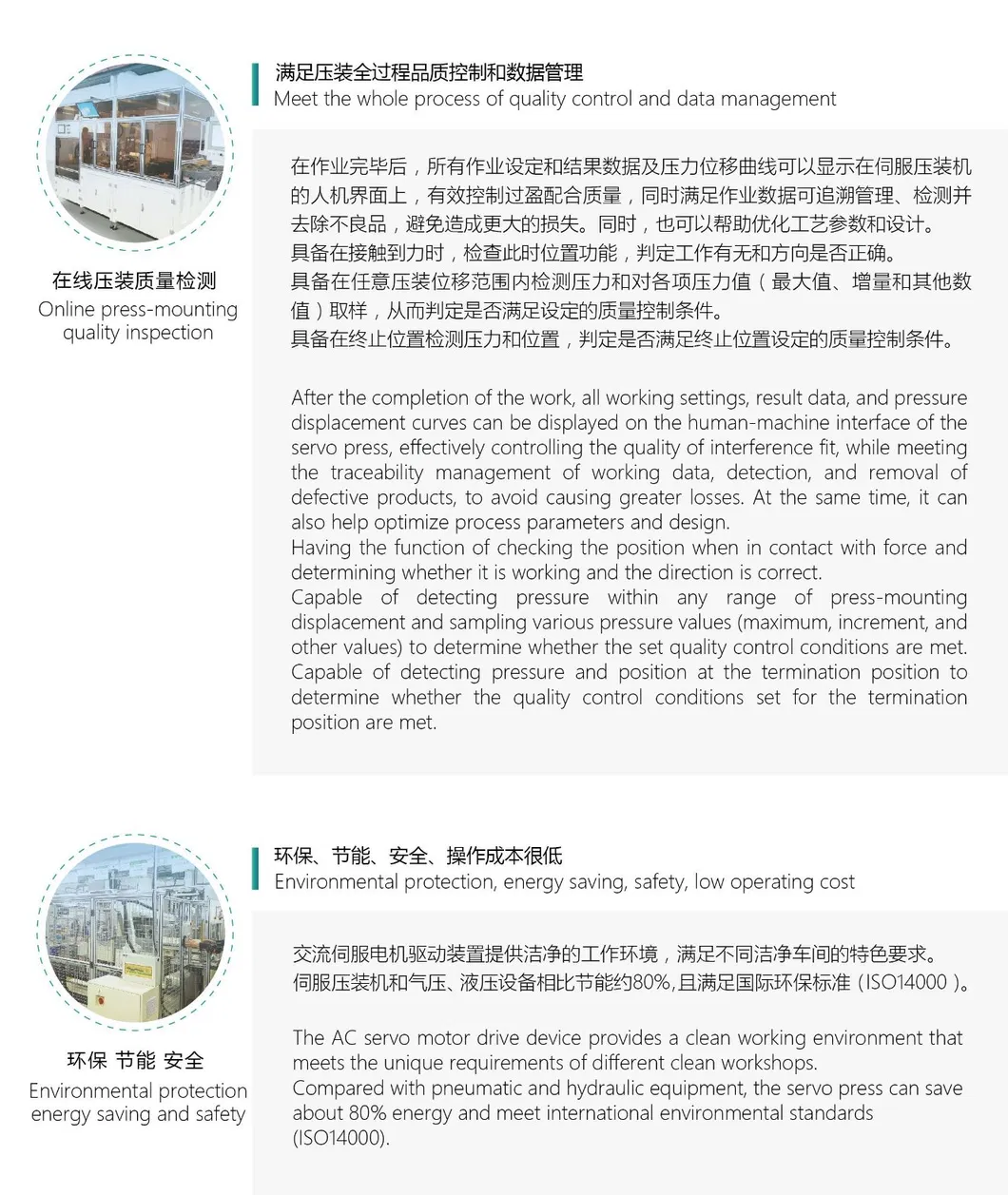

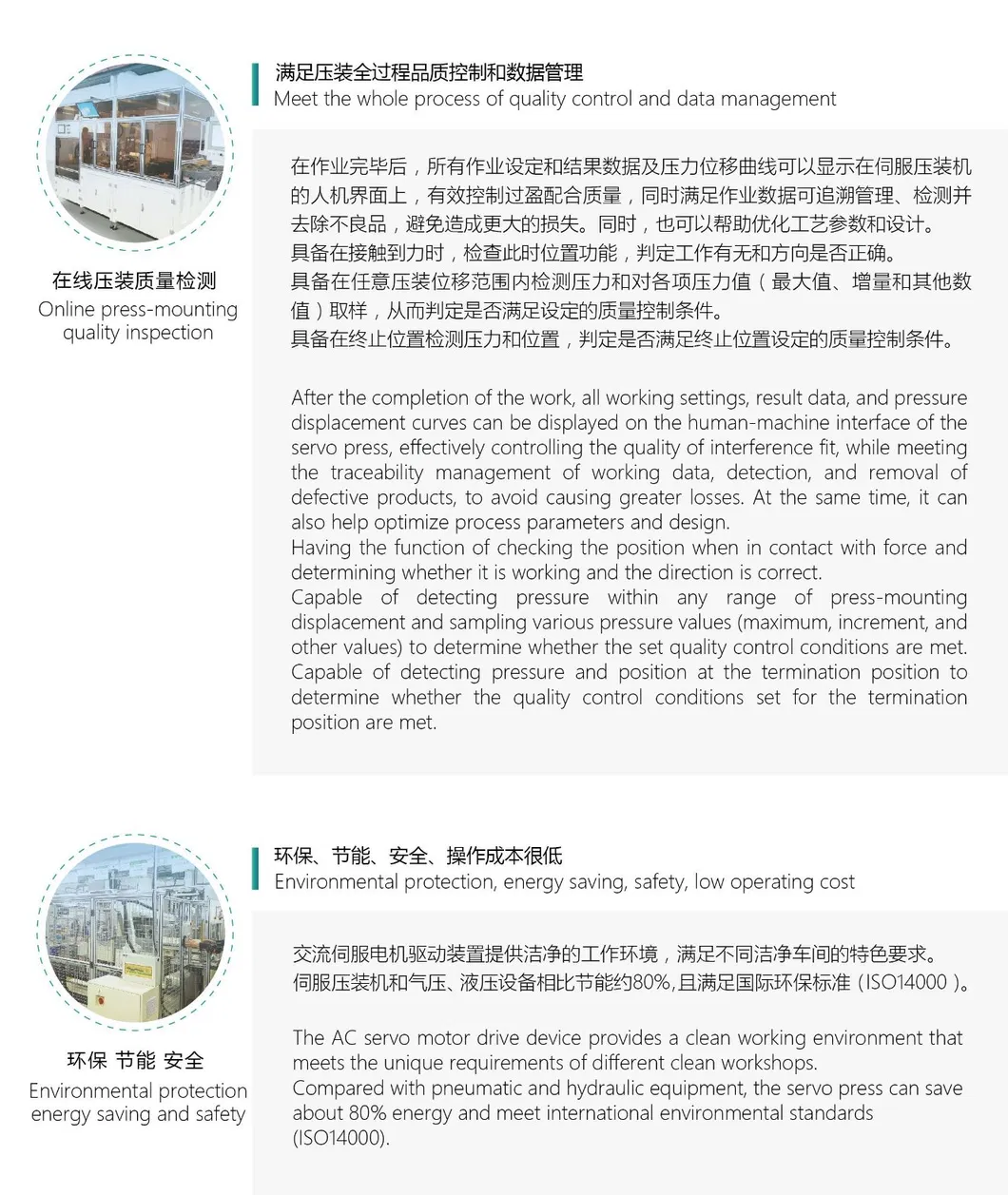

In the process of pressing the product, Tongjin servo press machine displays the current pressing position and pressing force in real time, and judges whether the interference is appropriate in time and accurately. At the same time, it displays the pressing curve of the entire force and displacement, which solves the disadvantages of traditional presses that can only be pressed and cannot be detected, and the low efficiency of the testing machine cannot be mass-produced.

The servo press machine can accurately test the pressure according to the set pressing depth, which can compensate for the working dimensional tolerance and ensure the final assembly precision. At the same time, the pressure and

displacement quality judgment area can be set, and online testing can ensure that the product is 100% qualified when press-fit.

The servo press machine can accurately control the press-fit speed, position,and pressure. Setting various press-fit procedures, including constant press-fit speed, setting precise position stop, setting precise force stop, setting precise press-fit displacement stop, and other working modes, makes it easy to complete the requirements of two or more stages of press-fit work. Within the stroke, the precise position of the machine can be arbitrarily set to stop, without the need to use expensive precision molds to ensure the precision of press-fit.

The positional repeatability is ± 0.01mm, and the pressure control accuracy is ±1% of the rated pressure.

SERVO PRESS MACHINE PRODUCT DEFINITION CODE

| TJ |

The abbreviation for Tongjin |

| SP |

The abbreviation for Servo Press Machine |

| 10 |

The actual tonnage 01:100KG 05:500KG 10:1T 100:10T 200:20T |

| C |

Servo press machine type C:C-Type F:Four-column D:Desktop |

| T |

Servo press machine control form T:Touch screen Computer |

For example: in principle, the C-type servo press machine is no more than 5

tons, and the desktop type servo press is no more than 2 tons.

TJ-sp-10ct means "C-type 1 ton touch screen servo press machine";

TJ-sp-80fc means "Four-column type 8 tons computer servo press machine";

TJ-sp-05dt means "Desktop type 500Kg touch screen servo press machine";

TJ-sp-10cc means " C-type 1 ton computer servo press machine".

Our company has successfully independently developed independent products such as Tongjin brand servo electric cylinders, intelligent servo press fit machines,Linear Electric Actuators,Heavy Duty Electric Cylinders,Servo Press Machine, etc., combined with six joint robots to achieve automated, safe, and unmanned intelligent assembly green unmanned production lines, providing a one-stop solution for intelligent assembly automation systems in factories.