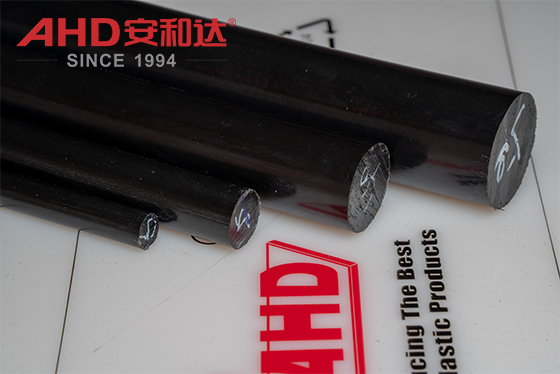

PA6 GF30 Rod Glass Fiber Material

Product Description

Pa6 Sheet is an engineering plastic rod made of nylon 6 (Polyamide 6) as the substrate, reinforced and modified by adding glass fiber (GF, usually with a content of 10% -40%) through melt blending process. Its appearance is usually a semi transparent to opaque milky white or light yellow cylinder, with a smooth surface and high dimensional accuracy. The diameter (such as Φ 10mm to Φ 200mm) and length can be customized according to customer needs.

PA6 GF rod significantly improves mechanical properties and thermal stability through the reinforcement effect of glass fiber, while retaining the wear resistance, self-lubricating properties, and chemical resistance of nylon substrate, making it a high-performance engineering plastic material.

The PA6 GF 30 Rod is engineered to provide superior mechanical properties, including high tensile strength, impact resistance, and excellent wear characteristics. The addition of glass fiber significantly enhances the material’s rigidity and thermal resistance, making it suitable for high-temperature environments. This rod exhibits low moisture absorption, ensuring dimensional stability even in humid conditions. It is also resistant to a wide range of chemicals, including oils, fuels, and solvents, which makes it highly versatile. The surface finish is smooth and consistent, allowing for easy machining and integration into complex assemblies. Additionally, the material offers good electrical insulation properties, making it suitable for use in electrical components and systems.

Nylon Round Bar

Characteristics

Mechanical performance

- High strength and rigidity: The addition of glass fiber significantly improves the tensile strength, bending strength, and elastic modulus (tensile strength can reach 150-200 MPa, which is more than 50% higher than pure PA6).

- Dimensional stability: low creep and high heat deformation temperature (HDT can reach 180-220 ℃), suitable for precision components in high-temperature environments.

- Impact resistance: Although glass fiber reinforcement may slightly reduce toughness, good notch impact strength (≥ 5 kJ/m ²) can still be maintained through modified formulations.

Physical performance

- Density: Approximately 1.35-1.45 g/cm ³ (higher than pure PA6).

- Wear resistance: High surface hardness, low friction coefficient, excellent wear resistance.

- Low water absorption rate: Glass fiber inhibits the moisture absorption of nylon, resulting in better dimensional stability (saturated water absorption rate<1%).

Chemistry and Weather Resistance

- Chemical corrosion resistance: It has resistance to oils, weak acids, weak bases, and common solvents such as gasoline and alcohol.

- Weather resistance: Outdoor aging resistance can be improved by adding UV resistant additives (customization required).

Processing performance

- Easy to cut, drill, tap and other mechanical processing, supporting CNC precision forming.

- Good thermal stability, suitable for hot forming and molding processes.

pa6 rod

Scope of application

Mechanical engineering: transmission and support components such as gears, bearings, guide rails, couplings, etc.

Automotive industry: engine peripheral components (such as intake manifold, cooling fan), electrical connectors, brackets.

Electronic appliances: circuit breaker casing, coil frame, connector base.

Chemical equipment: corrosion-resistant pipeline connectors, valve components, pump bodies.

Sports equipment: ski bindings, fishing gear accessories, fitness equipment structural components.

pa6 gf rod