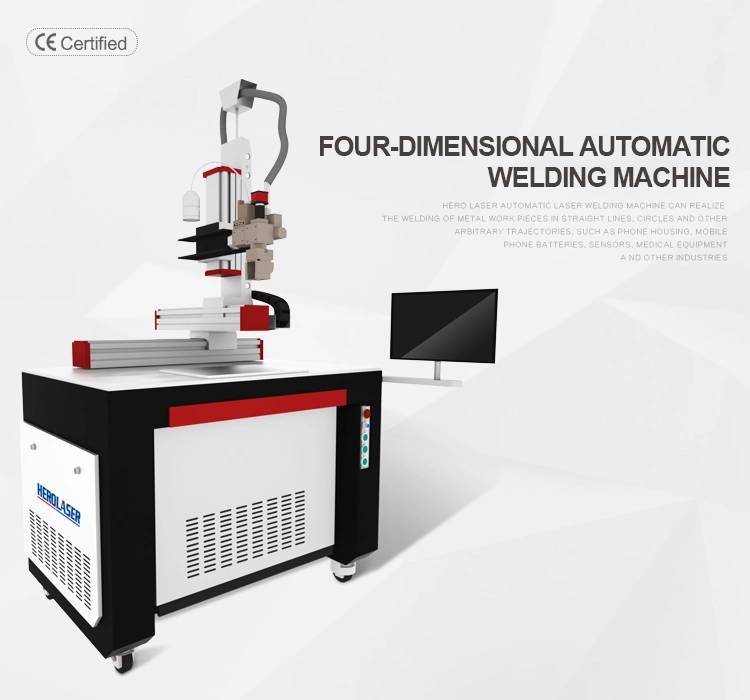

Platform Automatic Laser Welding Machine with CCD System

A platform automatic laser welding machine with a CCD system is an advanced welding equipment that combines automatic operation and a CCD (Charge-Coupled Device) system for improved welding accuracy and quality control.

The CCD system, which consists of a camera and image processing software, allows real-time monitoring and inspection of the welding process. It captures images of the weld area, enabling operators to closely monitor the welding progress and make necessary adjustments if needed.

The automatic operation of the machine involves pre-programmed welding paths and parameters, ensuring consistent and precise welds. The CCD system provides feedback to the control system, allowing for immediate adjustments based on the captured images.

This type of machine is commonly used in applications that require high-quality and accurate welding, such as the manufacturing of electronic components, medical devices, and automotive parts. It offers increased efficiency, reliability, and control over the welding process.

In summary, a platform automatic laser welding machine with a CCD system is a sophisticated tool that combines automated welding with real-time monitoring and quality control, resulting in improved precision and weld quality.

Applications

Automatic Production Line

Customized Fpc Laser Welding Machine

New Energy Battery Laser Welding Machine

Laser Welding Machine

| Main technical parameters of the equipment | ||

| Product Specifications | ||

| S/N | Main component name | Parameter |

| 1 | X axis effective stroke | 500mm |

| 2 | Y axis effective stroke | 300mm |

| 3 | Z axis effective stroke | 300mm |

| 4 | Dimensions | 1500×1400×1900mm |

| 5 | Machine weight | 280kg |

| 6 | Module operating speed | Y axis:10m/min |

| X axis:10m/min | ||

| Z axis:5m/min | ||

| 7 | repeated positioning accuracy | ±0.02mm |

| 8 | Rotating table | Circle runout accuracy ≤0.05mm |

| 9 | electricity demand | 220V/380V |

| 10 | Average load power | 7.5KW |

| Equipment configuration list | |||||

| Configuration Parameter | |||||

| S/N | Name | Specifications & Models | QTY | Brand | Remark |

| 1 | Fixture mounting plate | 350mm×450mm | 1 | Herolaser | |

| 2 | Laser | According to sample welding requirements | 1 | MAX or IPG | |

| 3 | Motor | servo motor | 3 | Huichuan | |

| 4 | Computer | PC/Industrial Computer | 1 | Advantech | |

| 5 | Chiller | According to laser power | 1 | S & A | |

| 6 | Welding head | According to sample welding requirements | 1 | Herolaser | |

| 7 | CCD Visual observation system | camera | 1 | Microsan | |

| light source | Basler/LeTV Light Source | ||||

| 8 | Z axis module | 300mm stroke | 1 | Herolaser | X, Y axis screw lead 10mm, Z axis screw lead 5mm; screw accuracy: C7 |

| 9 | X axis module | 500mm stroke | 1 | Herolaser | |

| 10 | Y axis module | 300mm stroke | 1 | Herolaser | |

| 11 | Rotating table | Three-jaw rotary chuck | 1 | Herolaser | |

| 12 | Lower cabinet | Sheet metal welding, paint baking | 1 | Herolaser | |

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Laser Welding Machine,

Laser Rust Cleaning Machine,

Laser Cutting Machine,

Laser Marking Machine,

Handheld Laser Welding Machine,

Laser Rust Remove Machine