Keyboard Case CNC Manufacturing & Mechanical Sandblasting: Precision Meets Aesthetic Mastery

The fusion of CNC machining parts and advanced finishing techniques like mechanical sandblasting is redefining premium tech accessories, from Gaming Keyboards to luxurious men’s smart watches. By combining precision engineering with tactile refinement, industries now craft products that excel in both performance and elegance—such as smart watch cases and custom mechanical keyboard accessories. Here’s how CNC manufacturing and sandblasting elevate these essentials.

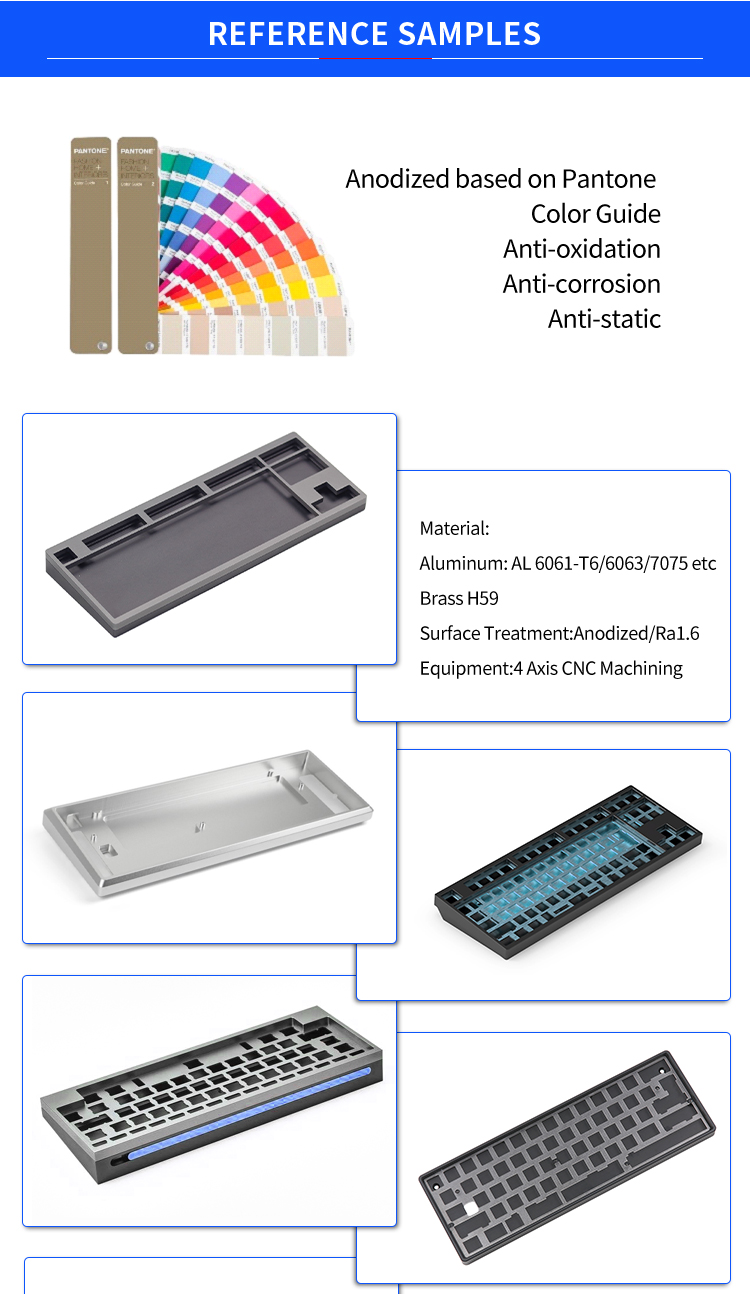

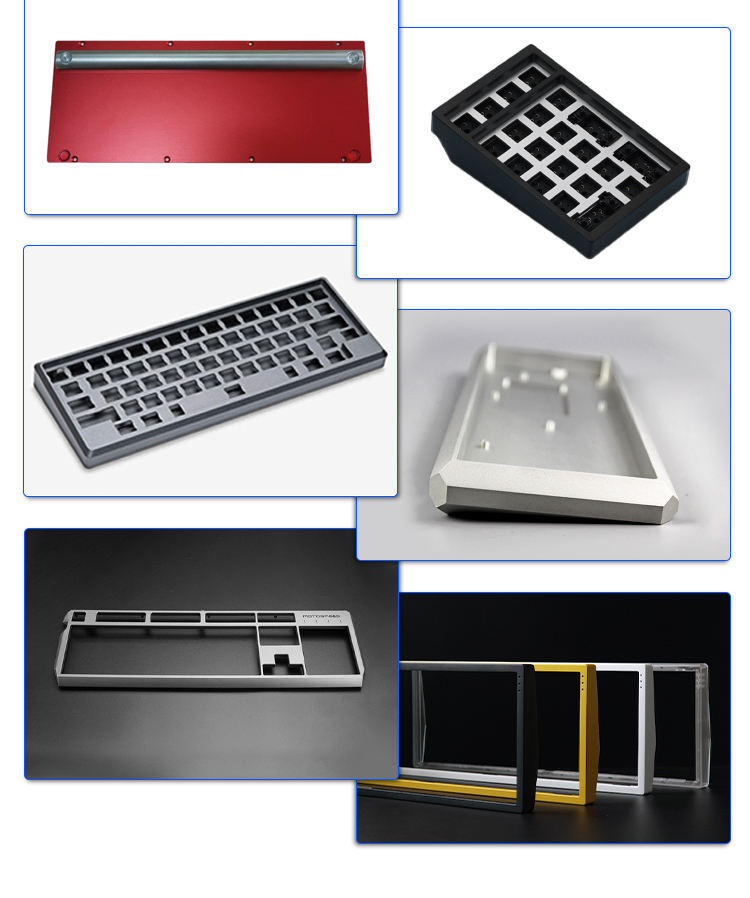

CNC milling parts enable the creation of complex, high-tolerance components. For keyboard cases, this means seamless integration of features like reinforced mounting points or ergonomic angles, ensuring durability for high-intensity gaming. Similarly, smart watch cases benefit from CNC’s ability to carve intricate designs, such as slim bezels or sensor housings, while maintaining structural integrity. Materials like aerospace-grade aluminium or stainless steel are milled to perfection, mirroring the robustness demanded by both Gaming Keyboards and luxury timepieces.

After CNC shaping, mechanical sandblasting adds the final touch. This process bombards surfaces with fine abrasives, achieving:

Sandblasting also unifies design language across accessories—imagine a brushed-metal watch case complementing a sandblasted aluminium keyboard, creating a cohesive tech ecosystem.

The overlap between mechanical keyboard accessories and smart watch cases lies in their reliance on precision manufacturing. A Gaming Keyboard’s aluminium case, sandblasted for a stealthy look, undergoes the same rigorous processes as a stainless steel watch case designed for luxury. CNC technology ensures both meet exacting standards, whether machining airflow cutouts for keyboard ergonomics or sculpting a chronograph’s curved lugs.

CNC and sandblasting empower personalization:

From the heft of a CNC-milled keyboard case to the refined texture of a sandblasted smart watch, modern manufacturing merges engineering and artistry. These processes not only enhance performance for Gaming Keyboards and luxurious men’s smart watches but also transform everyday tools into statement pieces. In a world where detail defines excellence, CNC and sandblasting prove that perfection lies in every grain and groove.

Manufacturing Technique

Item Name

Custom metal processing service sheet metal fabrication mechanical keyboard case metal fabrication

Process

Turning, milling, drilling, wire EDM, welding, casting,forging, assembly, etc

Materials

Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc.

Brass Alloy:3602 / 2604 / H59 / H62 / etc.

Stainless Steel Alloy:303 / 304 / 316 / 412 / etc.

Steel Alloy:Carbon Steel / Die Steel / etc.

Other Special Materials: Lucite / Nylon / Bakelite / etc.

Also, handle many other types of materials. Please contact us if your required material is not listed above.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Mechanical Keyboard,

Mechanical Watch,

Phone Case,

Quartz Watch,

Watch Accessories,

Keyboard Accessories