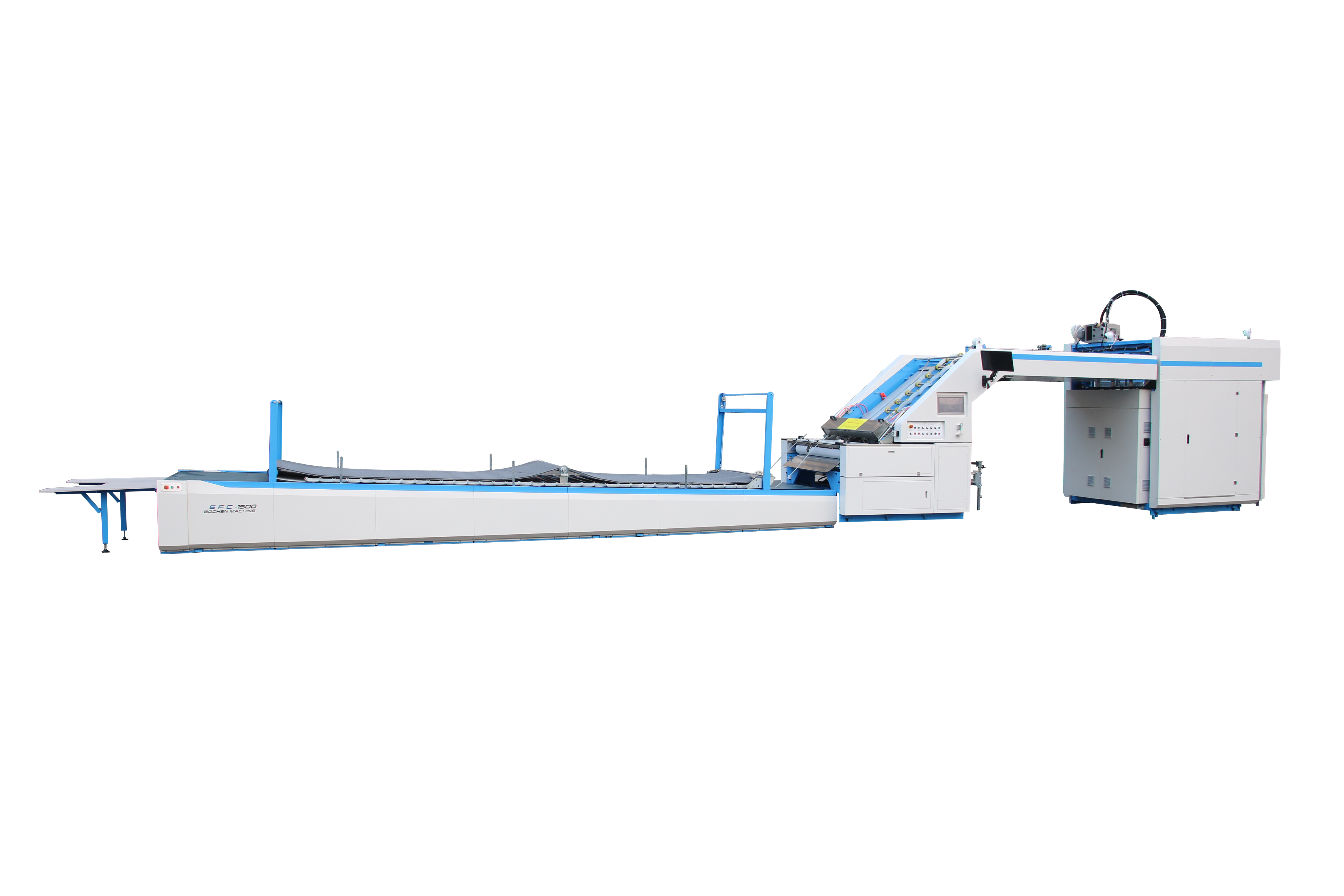

GFH-A Automatic High Speed Flute Laminating Machine

Machine overview:

GFH-A is the latest generation of high-speed automatic flute laminating machine developed by our company. The top paper of this machine adopts overlap feeding the principle of offset printer, and the top paper side gauge adopts the motion side gauge and the servo paper surface tracking and correction principle. It can automatically detect the height of the corrugated paper, automatically adjust the gap between the rollers, automatically adjust the amount of glue, and the laminating roller does not need to be scrubbed. The maximum laminating speed can reach 200 meters/minute (24,000 sheets/hour). High speed, high efficiency and high precision are your ideal choice.

Performance characteristics:

1. Top sheet Overlap feeding+non -stop correction, high speed without losing accuracy. Speed can reach 200 meters/min.

2. Bottom sheet big suction belt feeding system. It can work with both cardboard and corrugated board. Japan Nitta belt. And lead edge system is option.

3. The front pressure roller is made of new polyfluoroethylene material, which is free to wash, and then reduce the labor strength of the operator.

4. The whole machine has no handle, electric adjustment, automatic detection thickness, reducing the strength of the single -order work, and increasing the effective working time.

5. Because the machine uses overlap feeding, no gap correction without stop, so the unit time output increased by 50%, which greatly reduced the power consumption of the unit time, and it was truly increasing production and energy saving.

6. Adopts top sheet aligner system to ensure high accuracy. Feeding mode can be chosen overlap sheet or separation sheet type.

7. Digital design realizes automatic adjustment of glue volume. Automatic adjustment of the gap of the gluing roller (automatically according to the thickness of the bottom sheet).

8. The design of large stainless steel anilox roller (160mm in diameter) is stable and high-efficiency, coat evenly and save glue volume.

9. Automatic detection of top and bottom paper, automatic servo correction technology. Make the top paper automatically track and fit the bottom paper, and the accuracy is high.

10. The dual -use lifting platform, we can use the pre-stacker structure to push the pre -pile of paper into the platform. We can also push the stack of paper directly into the platform.

11. Use a circulating glue system to reduce glue loss and stabilize glue adhesion effect.

12. One -click adjustment of the whole machine (just enter the paper size).

13. Order memory function, one -click to transfer the previous order, convenient and fast.

14. Video monitoring.

15. Top sheet double sheet detection system.

SPECIFICATION:

|

MODEL |

GFH-1500A |

GFH-1700A |

GFH-1900A |

GFH-2200A |

|

Max Sheet |

1500×1500mm |

1700×1700mm |

1900×1900mm |

2200*2100mm |

|

Min Sheet |

400×400mm |

400×400mm |

500×500mm |

500*500mm |

|

Top Paper Thickness |

120-800g |

120-800g |

120-800g |

120-800g |

|

Max Speed |

200m/min |

200m/min |

200m/min |

200m/min |

|

Fitting Precision |

±0.8-1mm |

±0.8-1mm |

±0.8-1mm |

±0.8-1mm |

|

Power |

22KW |

25KW |

27KW |

30KW |

|

Bottom Paper Thickness |

≤10mm(A-F corrugated board) ≥400g cardboard |

≤10mm(A-F corrugated board) ≥400g cardboard |

≤10mm(A-F corrugated board) ≥400g cardboard |

≤10mm(A-F corrugated board) ≥400g cardboard |

|

Glue consumption |

B flute: 15gsm E flute: 20gsm |

|

||

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

flute laminating machine,

pile turner ,

litho laminating machine ,

gift box making machine,

book case making machine,

flip flop machine