Coalescing Filters

Coalescing Filters are probably the most important items of purification requirements in a compressed air system,which are designed not only to filter oil vapor and water, but also to filter solid particulates to an acceptable level assmall as 0.01micron in size. Usually, in the installation system, the first filter's purpose is to pre-filter, protect the highefficiency filters from bulk contamination so as to provide high quality

compressed air. If the air filters worked under damp or full of water adsorption condition, it would prevent the compressed air from getting through the filter element and the air low would force the liquid to get through from the pores of the element media. thus increase working pressure drop and reduce filtration performance.

Activated Carbon Filters

Oil vapor can easily get through the coalescing filters in a state of gaseous, so the adsorptive filter must provide large activated carbon adsorption bed. Because the damp air will reduce the adsorptive ability of the activated carbon, the adsorptive filter usually installed after the adsorptive dryer, in order to guarantee effective removal of oil vapor and peculiar odor. it's not used to remove the liquid oil or aerosols, thus poor maintenance and lack of pre-filter will accelerate its invalidation.

Feature& Benefit

1. Aluminum Alloy material, 15 years serve life for filter housing under working condition from temperature 1.5ºC~80ºC.| PF | AO | AA | AX | ACS | AR | AAR |

| As a primary filter, particles whose diameter more than 5μm can be remove,the maxi. residual oil content is negligible | High efficiency general protection, dust particles, water mist & oil mist whose diameter more than 1μm can be removed, the residual content of oil mist does not exceed 0.6mg/m³ (21ºC),1ppm(w). | High effiency oil remove filtration, dust particles, water mist and oil mist whose diameter more than 0.01μm can be removed, the residual content of oil mist does not exceed 0.01mg/m³(21ºC),0.01ppm(w) | Ultra-efficient filtration, dust particles, water mist&oil mist whose diameter more than 0.01μm can be removed, the residual content of oil mist does not exceed 0.001mg/m³(21ºC),0.001ppm(w) | Dust particles whose diameter more than 0.01μm, oil vapor &odor can be removed, the maxi. resident content of oil vapor does not exceed 0.003mg/m³(21ºC),0.003ppm(w) | Dust particles whose diameter more than 1μm can be removed | Dust particles whose diameter more than 0.01μm can be removed |

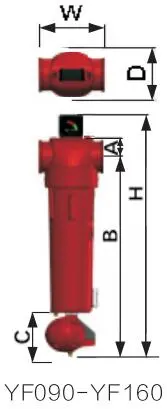

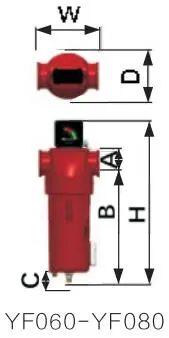

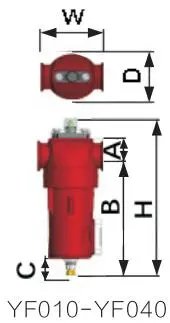

| Model | Pipe size | Flow rates | Dimension (mm) | |||||||

| L/S | m3/min | scfm | W(Width) | D(Depth) | H(Height) | A | B | C(clearance for housing) | ||

| YF010 | RC1/2" | 16.7 | 1.0 | 35.3 | 96 | 79 | 261 | 29 | 198 | 118 |

| YF020 | RC3/4" | 25.0 | 1.5 | 53.0 | 96 | 79 | 261 | 29 | 198 | 118 |

| YF030 | RC3/4" | 30.0 | 1.8 | 63.6 | 96 | 79 | 295 | 29 | 233 | 153 |

| YF040 | RC1" | 33.3 | 2.0 | 71.0 | 96 | 79 | 295 | 29 | 233 | 153 |

| YF060 | RC1" | 60.0 | 3.6 | 127.0 | 138 | 111 | 403 | 37 | 296 | 208 |

| YF070 | RC1" | 83.3 | 5.0 | 177.0 | 138 | 111 | 503 | 37 | 396 | 303 |

| YF080 | RC1-1/2" | 125.0 | 7.5 | 265.0 | 138 | 111 | 503 | 37 | 396 | 303 |

| YF090 | RC2" | 166.7 | 10.0 | 353.1 | 174 | 142 | 736 | 58 | 607 | 469 |

| YF100 | RC2-1/2" | 216.7 | 13.0 | 459.0 | 174 | 142 | 736 | 58 | 607 | 469 |

| YF110 | RC2" | 283.3 | 17.0 | 600.0 | 174 | 142 | 1016 | 58 | 887 | 794 |

| YF120 | RC2-1/2" | 316.7 | 19.0 | 671.0 | 174 | 142 | 1016 | 58 | 887 | 794 |

| YF130 | RC3" | 416.7 | 25.0 | 883.0 | 220 | 184 | 793 | 74 | 649 | 514 |

| YF140 | RC4" | 466.7 | 28.0 | 989.0 | 220 | 184 | 793 | 74 | 649 | 514 |

| YF150 | RC3" | 683.3 | 41.0 | 1448.0 | 220 | 184 | 1050 | 74 | 906 | 764 |

| YF160 | RC4" | 800.0 | 48.0 | 1695.0 | 220 | 184 | 1050 | 74 | 906 | 764 |

| Technical requirements | Maximum operating pressure: 10 barg Operating temperature: 1.5°C~80°C. | |||||||||

| Pressure | Barg | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Psig | 15 | 29 | 44 | 59 | 73 | 87 | 100 | 116 | 131 | 145 | 160 | 174 | 189 | 203 | 219 | 232 | |

| Correction factor | 0.38 | 0.53 | 0.65 | 0.76 | 0.85 | 0.93 | 1.00 | 1.07 | 1.13 | 1.19 | 1.23 | 1.31 | 1.36 | 1.41 | 1.46 | 1.51 | |

Replacements & Spare Parts

Successful Cases

YUKA service

a. Providing professional consultation, technical support and special solutions

b. Providing timely feedback on complaints

c. Providing perfect after sales service and warranty

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Compressed Air Dryer,

Compressed Air Filter,

Water Gas Separator,

Condensate Auto Drain ,

Air Filter Element,

Differential Pressure Gauge