The Versatile Applications of Transparent Coated PET Printable Rigid Film

Introduction

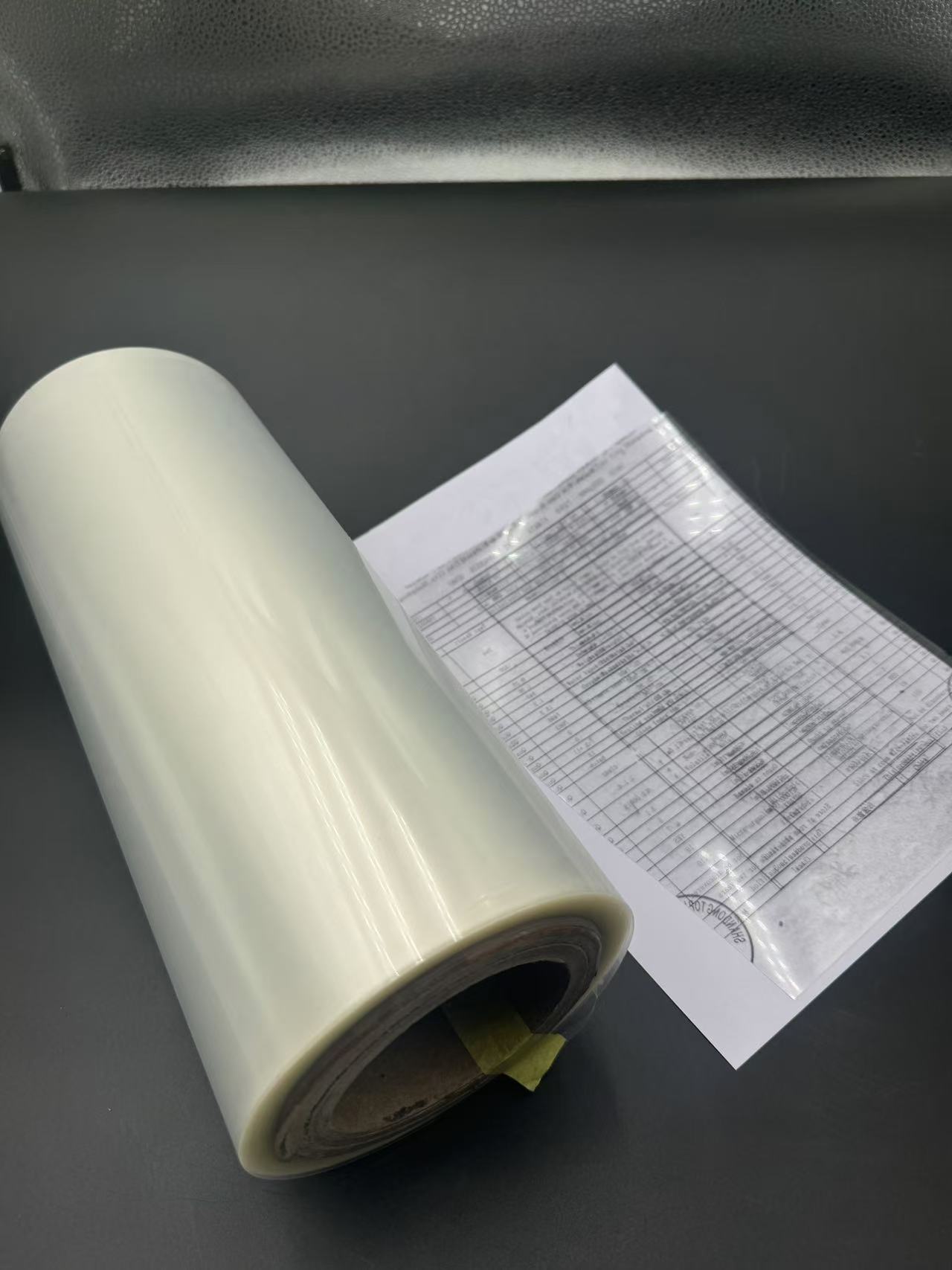

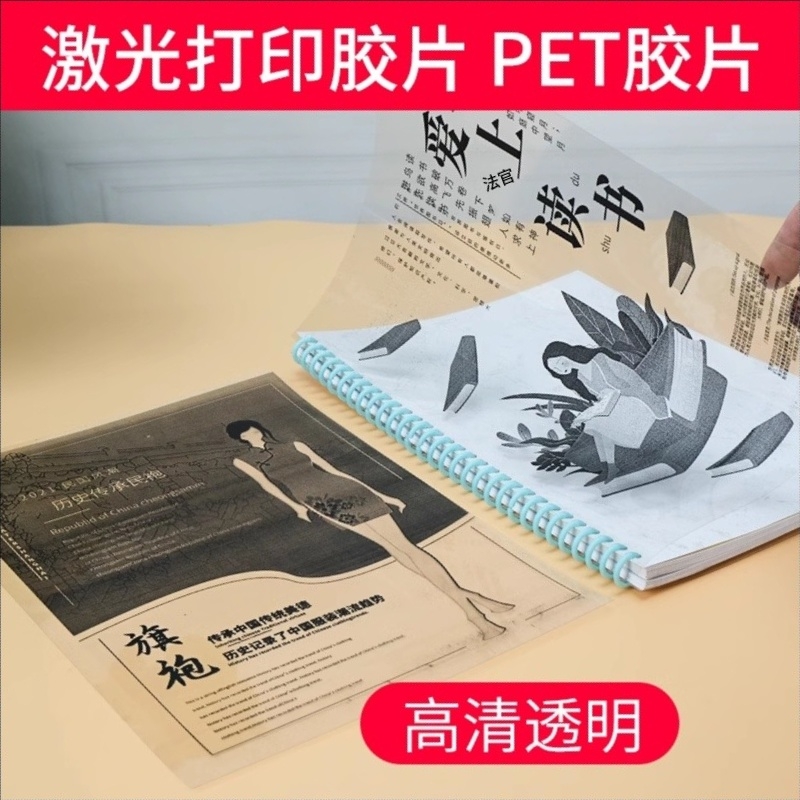

One of the most alluring features of this film is its exceptional transparency and clarity. The absence of impurities and the precisely controlled manufacturing conditions ensure that light passes through the film with minimal distortion. In applications like product labels, this transparency allows consumers to have a clear view of the underlying product, enhancing visual appeal. In medical imaging prints, where accurate visualization of minute details is crucial, the high clarity of the film enables healthcare professionals to make precise diagnoses. For example, in the printing of ultrasound or MRI images, the film faithfully reproduces the intricate patterns and shades, providing a reliable medium for analysis.

Mechanical Properties

Printability

The coated surface of the PET film is engineer

Barrier Properties

While primarily known for its printing capabilities, the transparent coated PET film also possesses decent barrier properties. It offers resistance against moisture, gases such as oxygen and carbon dioxide, and c

Chemical Resistance

PET, in its inherent structure, has good chemical resistance, and the coating further bolsters this property. It can withstand exposure to a range of chemicals, including common solvents, acids, and alkalis. In industrial settings where labels may come into contact with cleaning agents, lubricants, or other chemicals, the film remains intact, protecting the printed content. In medical laboratories, where reagents and disinfectants are prevalent, the chemical resistance of the film ensures that the printed labels on equipment, samples, and storage containers stay legible and unaffected.

Manufacturing Process of Transparent Coated PET Printable Rigid Film

PET Film Formation

Coating Application

Architects and interior designers

Educational Prints

In educational institutions, the film is being s.

Applications of Transparent Co 单刷 PET Printable Rigid Film in Medical Printing

Medical Imaging Prints

Medical Device Labels

Medical devices, from simple syringes to complex surgical equipment, require labels that are not only informative but also durable and sterile. The transparent coated PET film is used to print labels that contain device identification, operating instructions, sterilization dates, and safety warnings. The film's chemical resistance ensures that the labels remain legible even when exposed to disinfectants and cleaning agents used in medical facilities. The barrier properties protect the printed information from moisture and microbes, maintaining the sterility of the device and the clarity of the label throughout its use and storage. A surgical implant labeled with this film provides clear instructions to the medical team while remaining intact during the sterilization process and storage in the operating room.

Pharmaceutical Packaging Prints

Advantages of Using Transparent Coated PET Printable Rigid Film

Visual Appeal and Marketing Impact

Durability and Longevity

The combination of the PET base material's strength and the protective coating's properties results

Versatility in Ink Compatibility

The specially designed coating on the film allows it to work well with various ink types, from solvent-based inks for outdoor applications with high weather resistance requirements to water-based inks for indoor use with environmental and safety considerations. This versatility gives printers and manufacturers the freedom to choose the most suitable ink for their specific projects, whether it's a large-format outdoor billboard or a delicate medical label.

Information Integrity and Preservation

Recyclability

Case Studies of Transparent Coated PET Printable Rigid Film in Practice

Case Study 1: Food Labeling for a Premium Brand

Case Study 2: Architectural Firm's Presentation Upgrade

An architectural firm was looking for a better way to present their designs to clients and stakeholders. They switched to using transparent coated PET printable rigid film for printing their floor plans and 3D renderings. The film's rigidity and clarity allowed the prints to be easily overlaid on building models, providing a more immersive and interactive experience. Clients could visualize the proposed designs more vividly, leading to quicker approvals and a more collaborative design process. The durability of the film also meant that the prints could be reused in multiple meetings and presentations, saving time and resources.

Case Study 3: Hospital's Medical Imaging Solution

A l

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

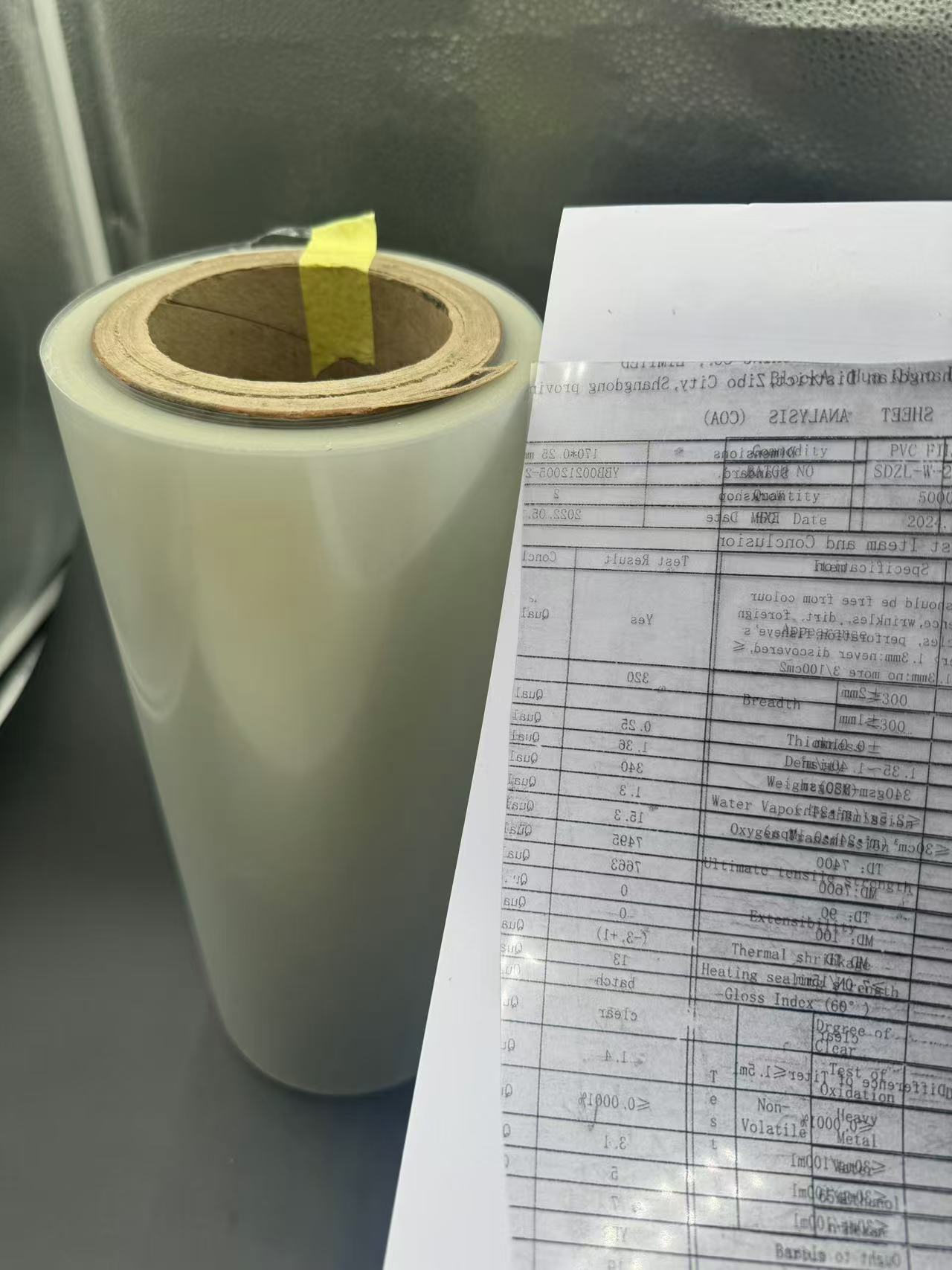

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film,

PC Film ,

PP Film,

Other plastic packaging products