2.4 Transparency and Printability

2.4 Transparency and Printability

PA/PE film is quite transparent, which makes it easier for consumers to view the content of the package. This is quite beneficial in food packaging because it enhances the appearance of the product and helps consumers make better choices. For example, in fruit boxes, the transparency of the film showcases the freshness and quality of the fruits inside. The film's surface is also receptive to printing, enabling manufacturers to print attractive labels, nutritional information, branding elements, and product details directly onto the package. High-quality printing not only provides essential information to the consumers but also adds to the overall aesthetic value of the product, making it stand out on the shelves.

2.5 Chemical Resistance

The film is chemically resistant to a wide range of substances, which is important in both food and pharmaceutical packaging. It does not react with the food or drug products, ensuring the safety and integrity of the packaged items. In food packaging, it can withstand contact with various food acids, oils, and spices without degrading or leaching harmful substances. In pharmaceutical packaging, it is compatible with different drug formulations and does not affect the potency or stability of the medications.

3. Application in Food Packaging

3. Application in Food Packaging

3.1 Food Blister Boxes

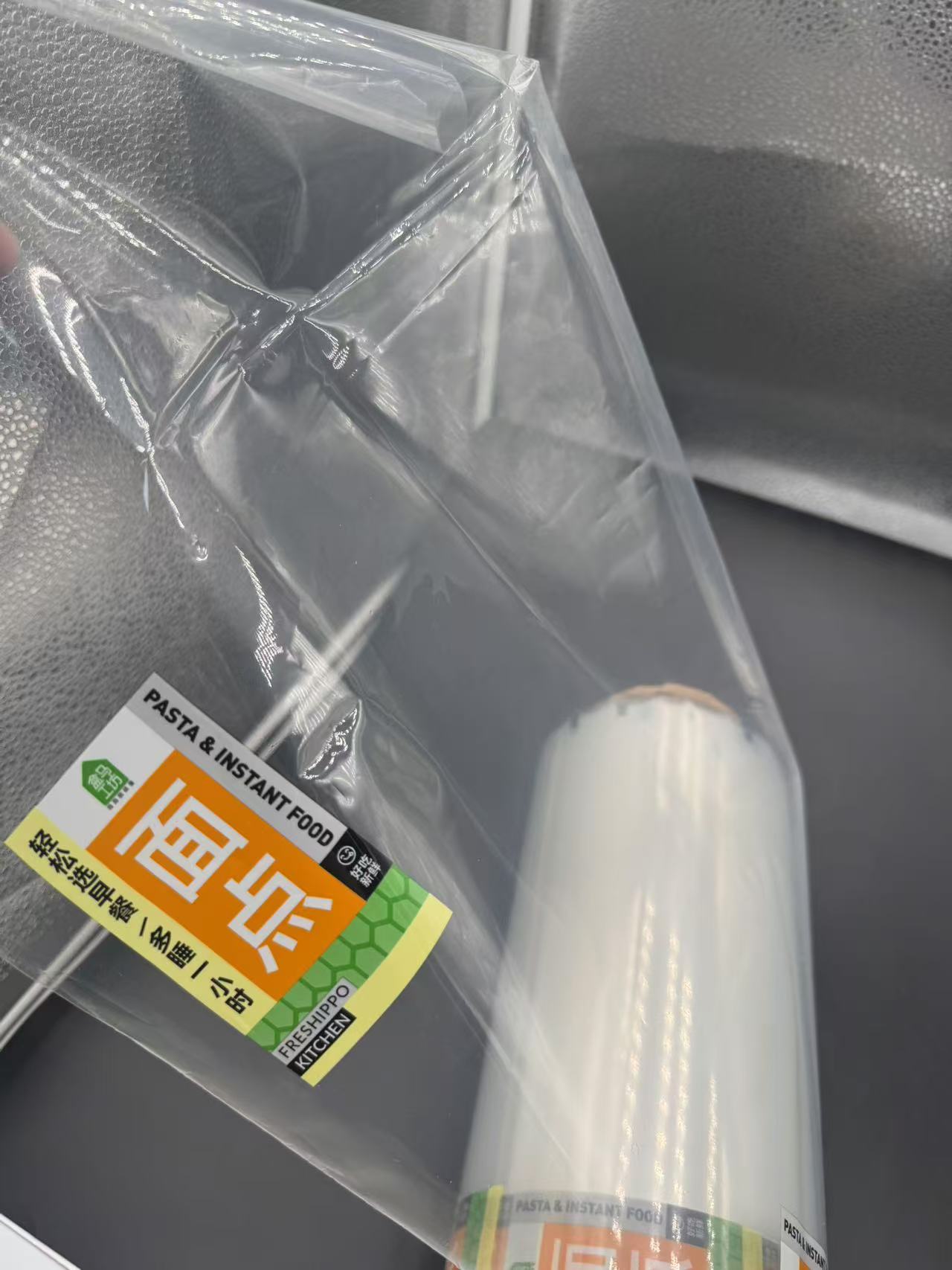

PA/PE film is widely used in the production of food blister boxes. The process begins with the thermoforming of the film. It is heated to the extent that it becomes pliable and molded into the shape of the blister cavity by vacuum or pressure-forming techniques.

3.2 Fruit Boxes

3.2 Fruit Boxes

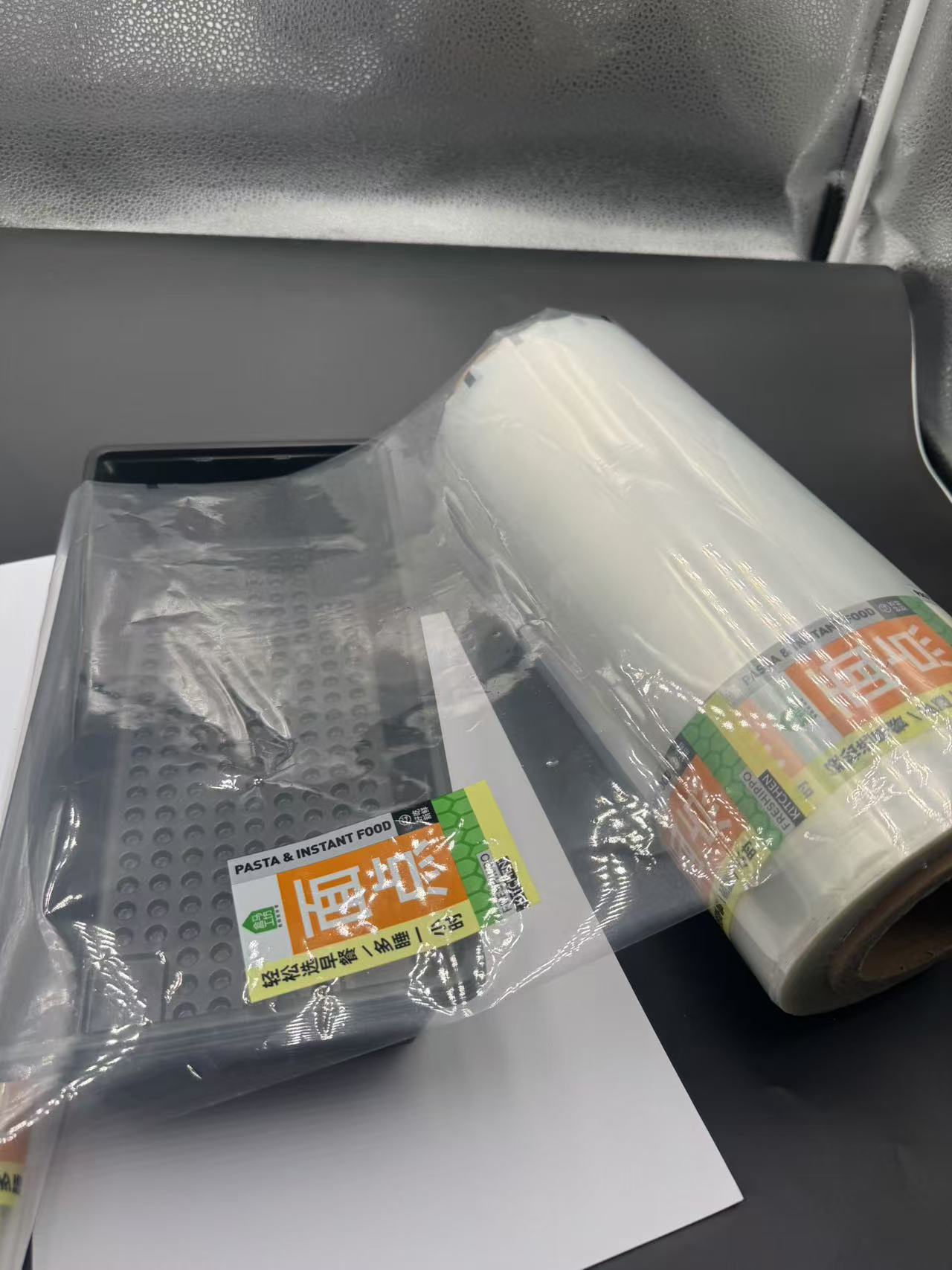

3.3 Cutlery Boxes

For the packaging of cutlery, PA/PE film is one of the best solutions. The high mechanical strength of the film prevents the sharp edges from the cutlery items from puncturing through the packing and creating hazards.

3.4 Beverage Cups

3.4 Beverage Cups

PA/PE film is used in the production of lids for beverage cups. The film is heat-sealed onto the cup rim, forming a tight seal that prevents any leakage of the beverage. The barrier properties of the film help to maintain the carbonation and flavor of carbonated drinks and prevent the absorption of odors from the surrounding environment for other beverages. The transparency of the film allows consumers to see the contents of the cup,

4. Application in Pharmaceutical Packaging

4. Application in Pharmaceutical Packaging

4.1 Pharmaceutical Seals

In the pharmaceutical industry, PA/PE film is used for sealing various types of pharmaceutical packaging, such as blister packs and bottles. The excellent barrier properties of this film protect the drugs from moisture, oxygen, and those environmental conditions that can contribute to degradation of their quality and potency.

5. Manufacturing Processes of PA/PE Film

5. Manufacturing Processes of PA/PE Film

5.1 Coextrusion Process

Manufacturing of PA/PE film involves a coextrusion process normally. In this process, the PA and PE resins are melted separately and then combined in a coextrusion die. The die is designed to form a multilayer structure whereby the PA layer and the PE layer are extruded together in one film. Depending on the specific requirements of the packaging application, different thicknesses and ratios of the PA and PE layers can be produced. The coextrusion process requires precise control of temperature, pressure, and flow rate to ensure the uniformity and quality of the film. The addition of additives, such as antioxidants, slip agents, and antiblocking agents into the resins before extrusion can improve the film's performance or processing characteristics.5.2 ORIENTATION AND ANNEALINGAfter the coextrusion of the film,

it can be subjected to an orientation that enhances the mechanical properties. This can be done in machine direction, transverse direction, or biaxial direction through the stretching operation which aligns the polymer chains, making the film strong with enhanced stiffness.  5.3 Surface Treatment

5.3 Surface Treatment

To improve the printability and heat sealability of the film, surface treatment may be carried out. One common method is corona treatment, which uses a high-voltage electrical discharge to modify the surface energy of the film. This makes the surface of the film more receptive to inks and adhesives, thus giving improved printing and sealing results. Another method is plasma treatment, which can also enhance the surface properties of the film by creating reactive species on the surface. These surface treatments are of great importance for ensuring the proper adhesion of printed labels and the formation of strong heat seals in the packaging process.

6. Quality Control and Regulatory Compliance

6. Quality Control and Regulatory Compliance

6.1 Quality Control Measures

6.2 Regulatory Requirements

6.2 Regulatory Requirements

7. Benefits of PA/PE Film Usage

7.1 Product Protection

7.2 Packaging Efficiency

7.3 Aesthetic and Marketing Benefits

7.3 Aesthetic and Marketing Benefits

7.4 Versatility

7.4 Versatility

The film is pretty versatile and can be used for a wide array of packaging applications. It can be tailored to different product types, shapes, and sizes-from the small pharmaceutical tablet to large food blister boxes and beverage cups. This is just one of the reasons it stands out in so many industries because it can answer diversified packaging requirements with a single solution.

8. Potential Challenges and Solutions

8.1 Cost Considerations

8.2 Recycling and Environmental Impact

8.2 Recycling and Environmental Impact

9.3 Sustainable Packaging Solutions

Considering the current trends, much emphasis is directed toward sustainability, and the future of PA/PE

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

PVC Rigid Film,

PET PETG Rigid Film,

HIPS Film ,

PC Film,

PP Film,

Other plastic packaging products