Patented Rotor: Extended Service Life

Utility Model Patent No.: ZL201721349545.9

1.Hammer Shaft Hole

A 42CrMoAl alloy sleeve is embedded into the hammer shaft hole via interference fit using a 200-ton hydraulic press, which extends the service life by several times compared with traditional hammer shaft holes.

2.Hammer Shaft

The hammer shaft is manufactured through a process of rough turning, quenching and tempering, carburizing, and finish turning, to enhance its strength, toughness and hardness.

3.Main Shaft

Made of 42CrMo material, the main shaft undergoes rough turning, quenching and tempering, and finish turning. The mating surfaces are milled on a gantry boring and milling machine, resulting in a significantly longer service life than that of traditional main shafts.

4.Hammer Head

We adopt high-strength thermally bonded bimetallic high-chromium alloy hammer heads, which are provided to customers at cost price.

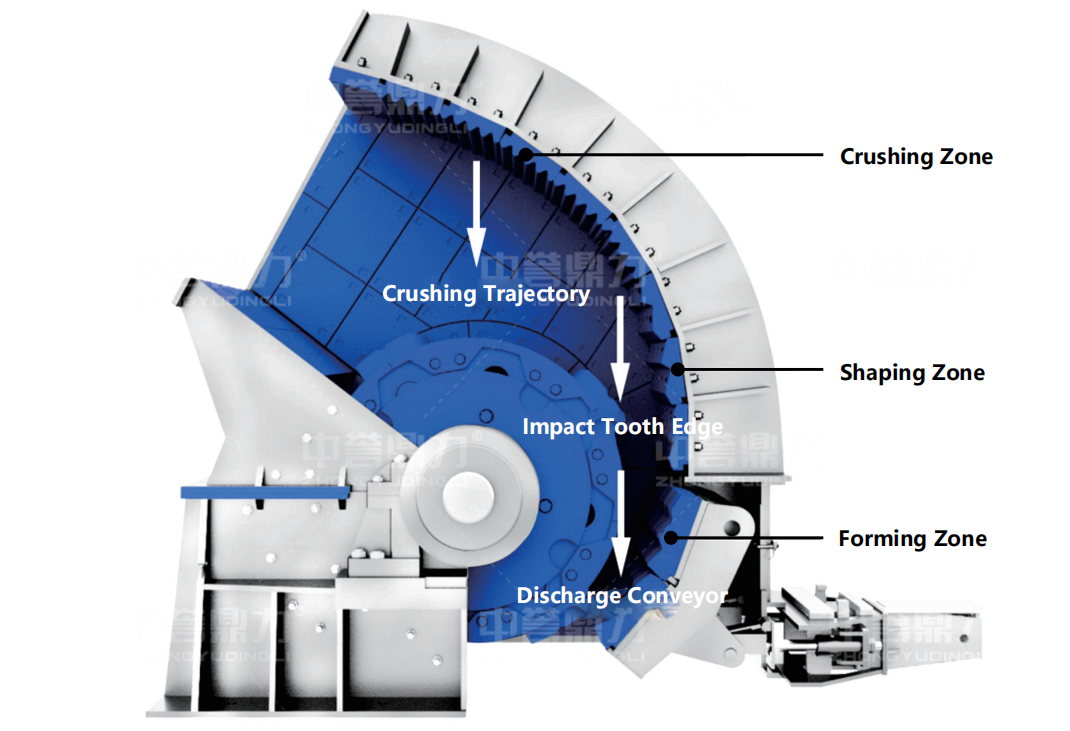

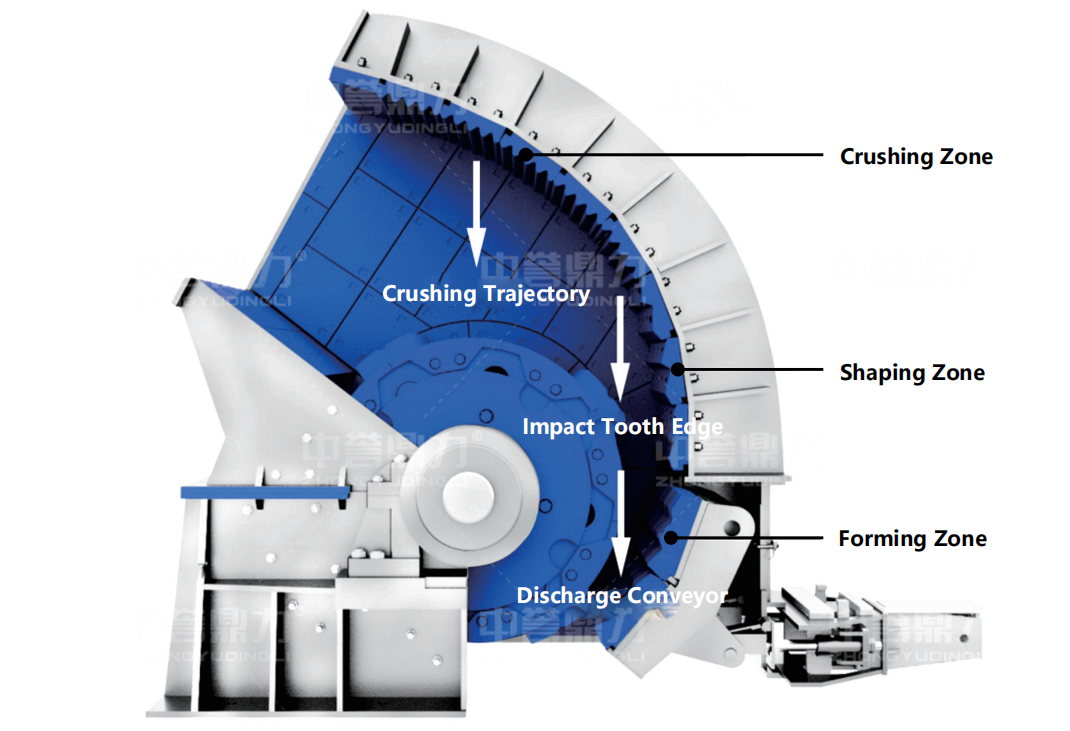

Three Impact Zones for Superior Particle Shape

The impact plate of the top impact zone features a downward wave pattern, with its impact trajectory positioned between the two rows of hammers on the rotor. The hammers crush the materials, while this impact zone shapes them. By guiding materials back between the two rows of hammers through the impact trajectory, it further enhances the crushing efficiency.

The second impact zone adopts a diamond-shaped impact design, with its movement trajectory located below the hammers. This design accelerates the downward flow of materials, shortens their residence time inside the machine chamber, and simultaneously performs impact shaping on the materials.

The third impact zone employs an inverted triangular impact structure that is gravity-flow enabled and spacing-adjustable.

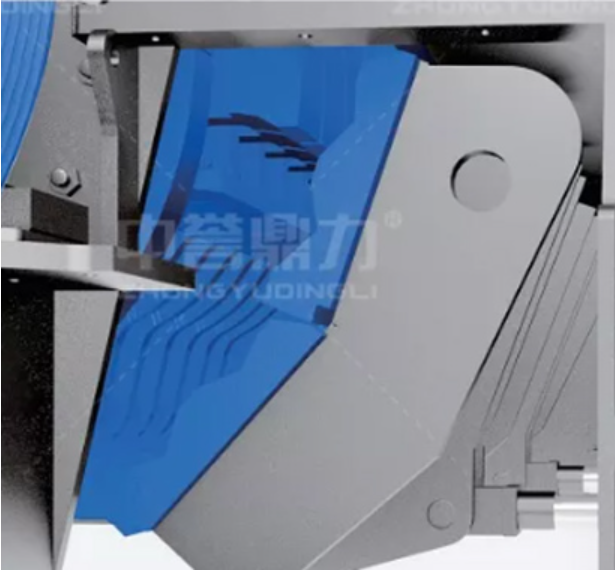

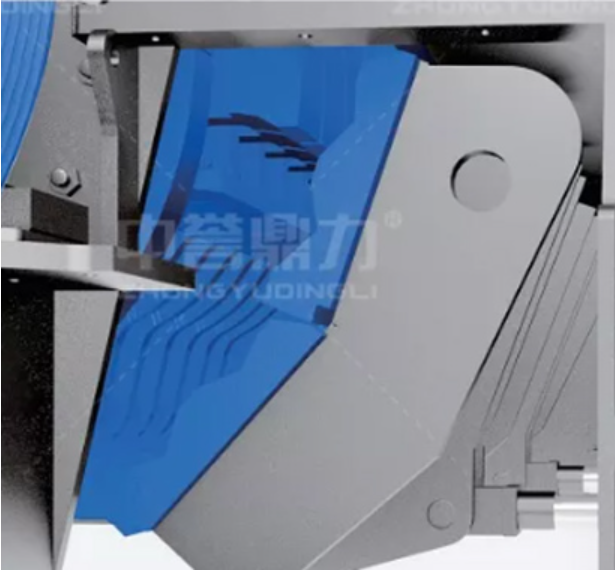

Gravity Flow Chute Design: Minimal Powder Generation

Gravity Flow Chute Design: Minimal Powder GenerationGaps are reserved on the adjustable impact plate of the third impact zone, allowing materials with a diameter smaller than the gap to flow out naturally. This design avoids re-crushing, boosts production capacity, and significantly reduces the powder generation rate. It serves as an ideal alternative to traditional impact crushers when processing appropriate materials.

Time-Tested Product

Building on the mechanical principles of traditional hammer crushers, impact crushers, box-type crushers, and all other machinery that crushes stone via hammers or blow bars, we have designed the Heavy Hammer Impact Crusher by integrating over 30 years of stone crushing experience.

Optimal Gradation

Thanks to multiple ingenuous designs including the three impact zones, finished product gravity flow, and adjustable impact liners, the finished aggregate achieves optimal gradation with low powder generation. It can meet the diversified requirements of customers.

Easy Maintenance

Equipped with 8 sets of hammer shaft holes (4 for standby use), the machine body is fitted with inspection doors for easy monitoring of operation status. A hydraulic shaft extractor is provided to facilitate the replacement of hammers and hammer shafts. All components are bolt-fastened for convenient disassembly, reducing maintenance time and costs.

Exquisite Manufacturing

All key components are protected with safeguards. They are processed using modern machinery and equipment such as gantry milling machines and hydraulic presses. We have established a dedicated Product Technology Department to continuously improve processing technologies and enhance product quality.

Technical Parameters of Heavy-duty HammerImpact Crusher

Gravity Flow Chute Design: Minimal Powder Generation

Gravity Flow Chute Design: Minimal Powder Generation