Puwei's Silicon Nitride Ceramic AMB Copper-clad Substrate represents the pinnacle of advanced ceramic substrate technology for demanding power devices and high-reliability electronic packaging. Utilizing Active Metal Brazing (AMB) technology, we bond high-conductivity copper to premium silicon nitride (Si₃N₄) ceramic, delivering exceptional thermal, mechanical, and electrical performance for next-generation SiC and GaN applications. This substrate is engineered as the ultimate solution for high-power microelectronic components requiring unmatched reliability.

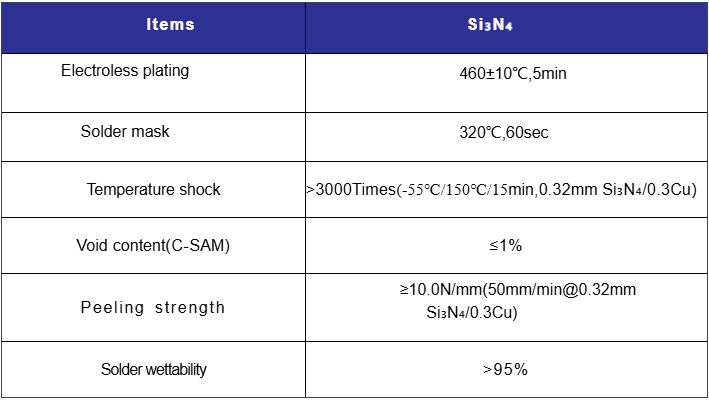

Our Si₃N₄ AMB substrates are characterized by precise, high-performance specifications crucial for reliable microelectronics packaging.

Base Material: High-purity Silicon Nitride (Si₃N₄). Cladding Material: Oxygen-free high conductivity copper. Thermal Conductivity: 80-90 W/m·K. Flexural Strength: >800 MPa. CTE: 3.2 ppm/°C. Dielectric Strength: >15 kV/mm. Peel Strength: >80 N/cm.

Ceramic Thickness: 0.25mm-1.0mm standard (0.2mm-2.0mm custom). Copper Thickness: 0.1mm-0.8mm. Maximum Size: 240mm × 280mm. Surface Flatness: <10μm/cm. Thick Copper Capability: Supports up to 0.8mm copper for higher current carrying capacity, ideal for advanced integrated circuit packaging.

Silicon nitride's unique microstructure prevents crack propagation under rapid temperature changes, making it ideal for harsh environments where alumina ceramic substrates or aluminum nitride ceramics may fail. This is critical for automotive and industrial power devices.

The thermal expansion coefficient of 3.2 ppm/°C closely matches Silicon Carbide (SiC) and Gallium Nitride (GaN). This minimizes interfacial thermal stress, extending product lifetime and enhancing reliability in high-power microelectronics applications.

With flexural strength exceeding 800 MPa, it provides 3-5x greater mechanical robustness than standard alumina. This ensures integrity under vibration and mechanical stress in electric vehicle powertrains and heavy industrial equipment.

Active Metal Brazing creates strong chemical bonds between ceramic and copper, offering superior thermal cycling performance and long-term reliability compared to traditional Direct Bonded Copper (DBC) methods. This advanced metallized ceramics process is key for high-reliability electronic packaging.

Main inverters, DC-DC converters, and onboard chargers requiring robust performance under vibration, thermal cycling, and high power density. Essential for next-generation SiC-based power devices.

Solar inverters and wind power converters demanding long-term reliability and excellent thermal shock resistance in outdoor environments with wide temperature fluctuations.

High-power drives for manufacturing and automation equipment requiring exceptional mechanical strength and thermal cycling performance in harsh industrial settings.

Mission-critical power electronics where the highest levels of reliability, mechanical robustness, and performance under extreme conditions are non-negotiable.

While optimized for thermal management, its excellent dielectric properties also support demanding RF circuits and microwave applications where reliability is paramount.

Our production ensures the highest purity, density, and dimensional accuracy for critical insulation elements in power modules.

Puwei products meet the highest international standards for quality and reliability.

We tailor Si₃N₄ AMB substrates to your exact requirements for advanced electronic packaging.

If you are interested in the product, contact 2bvideo.com for more information for more information

The information of 2bvideo.com limited shown above is provided by the user or collected on the network. Video 2B does not guarantee the authenticity,accuracy and legitimacy of 2bvideo.com limited information. Video 2B does not involve legal relationships and disputes between users arising from transactions other than secured transactions on this website. Disputes shall be settled by you through negotiation. If you are the person in charge or relevant employee of this enterprise, if you find that the enterprise information is incorrect or want to manage thiscompany, please contact us jacklee1558@gmail.com, after you claim the enterprise, you can obtain management permission, publish supplyand demand information, bring consulting orders, and remove page advertisements.

Main Product:

Alumina Ceramic Substrates,

Aluminum Nitride Substrates,

Metallized Ceramics,

AlN Ceramics Disc,

DPC Substrate ,

DBC Ceramic Substrate